-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

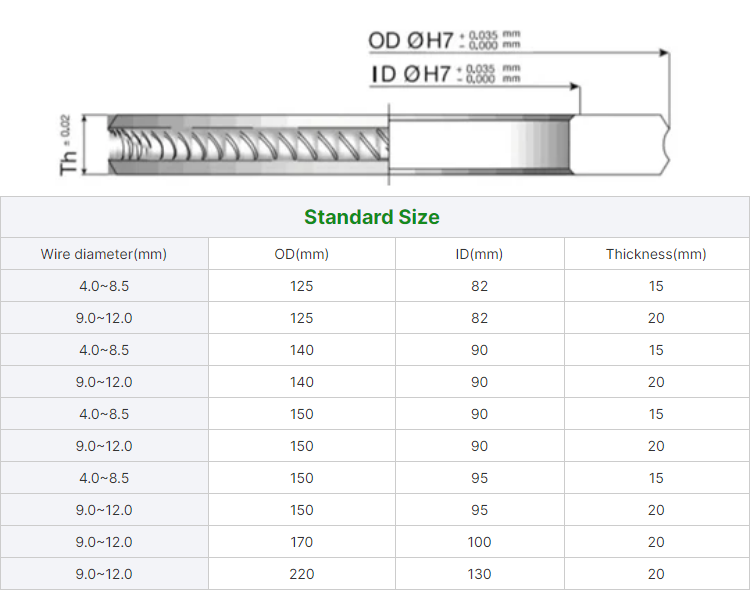

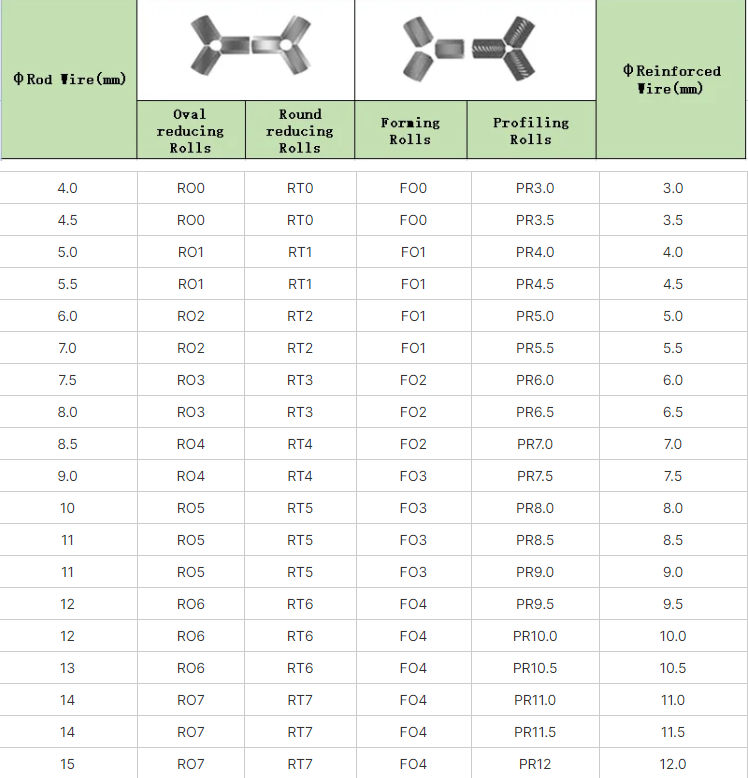

Cemented carbide rolls are rolls made of tungsten carbide and cobalt using powder metallurgy methods. They have good wear resistance and high impact resistance, superior performance, stable quality, high product processing precision, and are resistant to hard alloys. We have rich and mature production experience in the processing of high-quality alloy rolls. We have superb blank forming and precision processing capabilities. We have high-precision optical curve grinding, Zeiss three-coordinate inspection and other equipment. Both processing and acceptance can complete more precise dimensions and contours to high standards. Curved parts.

Item name :

Tungsten carbide cold heading blankGrade :

YG15 YGR30Hardness :

HRA86Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

TUNGSTEN CARBIDE ROLLERLogo :

HENGRUIpackage :

cartonDetailed Description:

In the process of turning cemented carbide rolls, the hardness of the tool itself must be higher than the hardness of the workpiece being processed. Therefore, the tool materials currently used for turning cemented carbide rolls are mainly made of high-hardness, high-heat-resistant non-metallic binders cubic boron amide and diamond. host. For the processing of carbide rolls, Sidi Technology Co., Ltd. has very rich practical experience and can provide complete sets of carbide roll turning and grinding solutions.

As the main working consumable part of the rolling mill, the roll has a direct impact on product quality and production efficiency. Compared with rolls made of other materials, cemented carbide rollers have high hardness, high compressive strength, good wear resistance, good corrosion resistance, small friction coefficient, low thermal conductivity, long service life, and high precision of rolled products. Due to its advantages such as good quality, it has become the main roll material for wire rod rolling, especially finishing rolling, pre-finishing rolling and intermediate rolling in high-speed wire rod mills. Each time the cemented carbide roller is ground, the amount of steel passed in a single groove reaches more than 800 to 1,200 tons, which is 10 times that of the ductile mill cast iron roller.

Tags :