-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

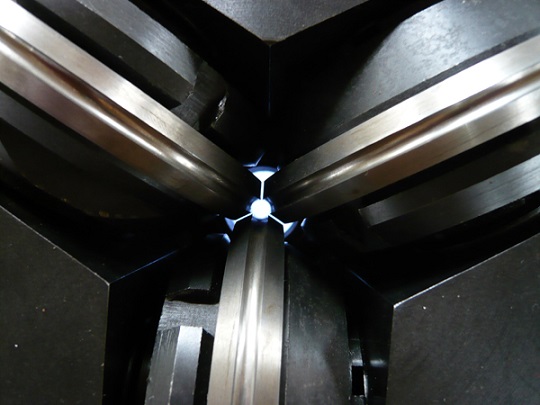

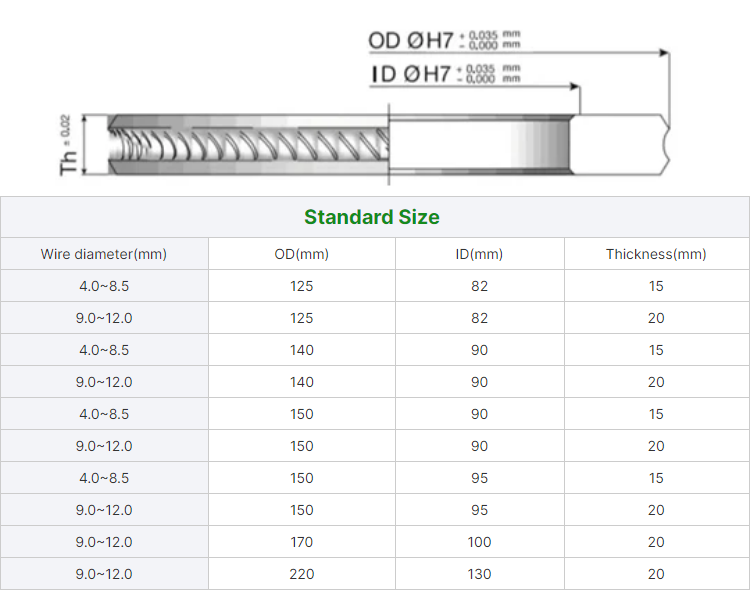

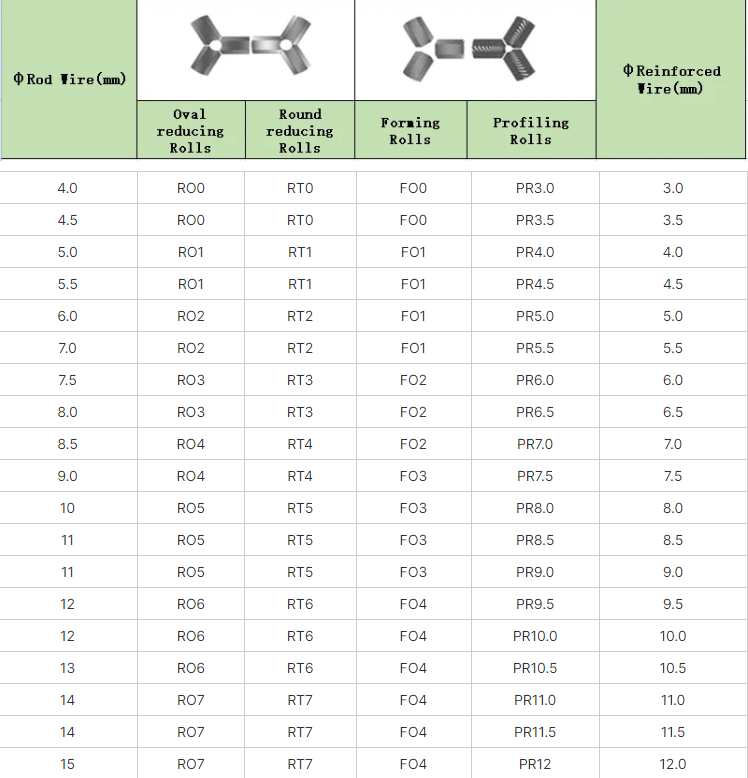

Cemented carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality.

Item name :

Tungsten Carbide Heading DieGrade :

YG15Hardness :

HRA86.5Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

Carbide rollerLogo :

HENGRUIpackage :

cartonDetailed Description:

In order to adapt to this requirement, hot rolling roll materials have been continuously improved and developed, from the early ordinary chilled cast iron, infinite chilled alloy cast iron, high chromium cast iron, high chromium cast steel: to the current widespread use abroad of high-speed steel and cemented carbide. The improvement and development of roll materials are closely linked to their preparation methods. The development of roll materials from single materials to composite materials has promoted the development of roll preparation methods, and greatly improved the performance-price ratio of roll materials and the service life of rolls. Among them, the preparation methods of roll materials are also constantly improving, from ordinary Casting developed to centrifugal casting and then to squeeze casting: from powder metallurgy to hot isostatic pressing and combustion synthesis.

Tags :