-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

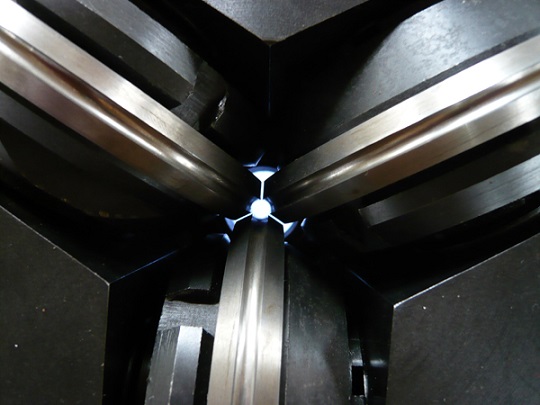

The main performance indicators of the roll are the strength of the core and the toughness and wear resistance of the working layer. The performance requirements for the finishing rolls of bar mills are mainly wear resistance and toughness, taking into account hot crack resistance and strength. Traditional bar mill rolls are usually made of integral centrifugally cast ductile iron rolls with a roll surface hardness of 74~78HSD. In order to further improve the wear resistance of the finishing rolls and increase the rolling capacity of the single groove, drawing on the experience of using cemented carbide roll rings in high-line finishing mills, in recent years, more and more manufacturers have adopted carbide roll rings instead of ductile iron rolls in bar rolling mills. more.

Item name :

Tungsten Carbide Heading DieGrade :

YG15Hardness :

HRA86.5Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

Carbide rollerLogo :

HENGRUIpackage :

cartonDetailed Description:

Renqiu Cemented Carbide Co., Ltd. adheres to the business philosophy of "innovation and self-hardening, and the Great Wall of Excellence", conscientiously implements the party's line, principles and policies, and adheres to Deng Xiaoping Theory, the important thought of "Three Represents", the Scientific Outlook on Development, and Xi Jinping's New Guided by the Thought on Socialism with Chinese Characteristics for the Times, we are determined to forge ahead and have the courage to innovate. We have made great progress in all aspects of work, which reflects the social responsibility and uprightness of important members of state-owned enterprises and central enterprises.

Tags :