-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

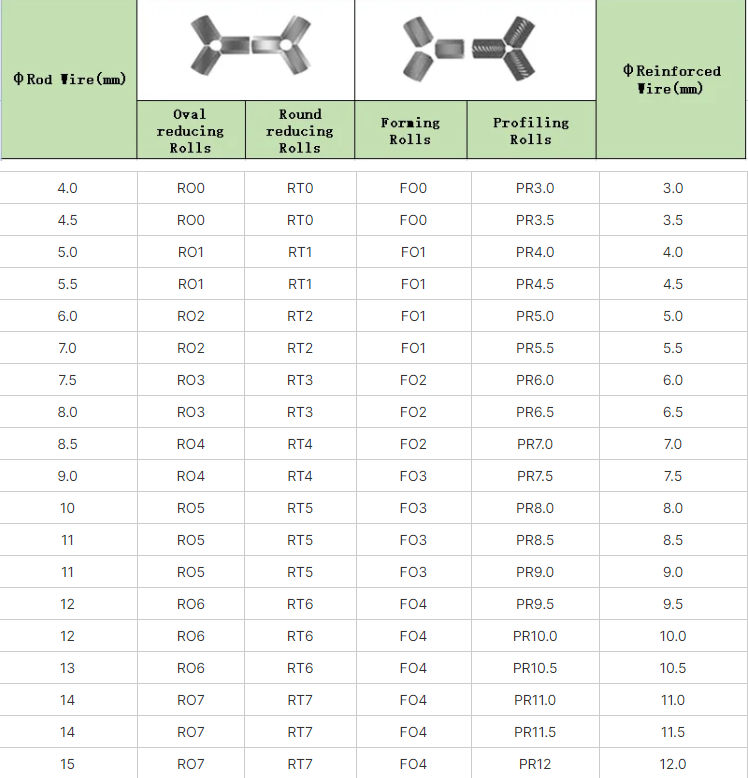

For key equipment such as rolls, the technical requirements are very high. It requires the selection of appropriate materials, hardness, contours, etc., and detailed and scientific design and manufacturing based on actual production conditions to ensure that the equipment can operate stably and efficiently and ensure product quality. and business benefits.

Item name :

Tungsten carbide cold heading blankGrade :

YG15 YGR30Hardness :

HRA86Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

TUNGSTEN CARBIDE ROLLERLogo :

HENGRUIpackage :

cartonDetailed Description:

The hardness of the roll should be selected to an appropriate value to ensure that excessive wear or scratches will not occur on the surface of the roll during material processing, thereby affecting the processing quality of metal materials. At the same time, the quality of the roll hardness also determines the degree of restriction and deformation ability of the metal material during the rolling process.

The accuracy standards of cold-rolled strip steel rolls mainly include core indicators such as surface roughness, rolling torque deviation, roll diameter difference under the same conditions, and roll roundness error. Among them, surface roughness and rolling torque deviation are key indicators to measure the surface finish and wear degree of the roll; while the roll diameter difference and roundness error directly affect the dimensional accuracy and angle of the strip, and are important indicators of the quality of the cold-rolled strip. factor.

Tags :