-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

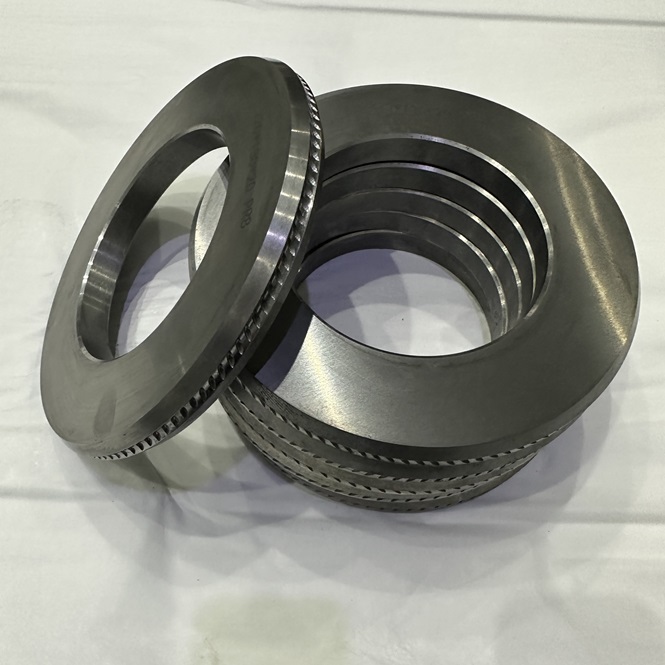

When judging the quality of a tungsten carbide roller, there are several important factors to consider:

Material Grade: The grade of Tungsten carbide cold roll is crucial. Tungsten carbide grades are standardized and designated by a combination of letters and numbers. Higher-grade materials typically exhibit better hardness, wear resistance, toughness, and overall performance.

Hardness: Tungsten carbide is known for its exceptional hardness. The roller should have a high hardness level to resist wear and maintain its shape during operation. Hardness is typically measured using the Rockwell or Vickers hardness scales.

Wear Resistance: The roller should have excellent wear resistance to withstand the abrasive nature of the application. It should be able to endure prolonged contact with the deformed steel bar without significant wear or degradation.

Coating: Some tungsten carbide rollers may incorporate coatings to further enhance their performance. These coatings, such as diamond-like carbon (DLC) or titanium nitride (TiN), can provide additional hardness, reduce friction, and prevent material buildup on the roller surface.

Dimensional Accuracy: The roller must have precise dimensions to ensure proper functioning and accurate shaping of the deformed steel bar. It should have tight tolerances and maintain its shape over time.

Surface Finish: The roller's surface finish should be smooth and free from defects to minimize friction and facilitate smooth material flow during the rolling process. A high-quality surface finish also helps prevent defects on the deformed steel bar.

Manufacturer Reputation: Consider the reputation and experience of the manufacturer or supplier. A reputable manufacturer with a track record of producing high-quality tungsten carbide rollers is more likely to provide reliable products.

When evaluating the quality of a tungsten carbide roller, it's important to consider both the material properties and the manufacturing quality. Consulting manufacturers or suppliers with expertise in tungsten carbide rollers can provide further guidance in selecting the right roller for your specific needs.