-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

Tungsten carbide roller has superior performance, stable quality, high precision, good wear resistance and high impact resistance. Carbide roller has high hardness, which is not affected by environmental or external temperature change, therefore it can be used in an extremely hot or cold environment.

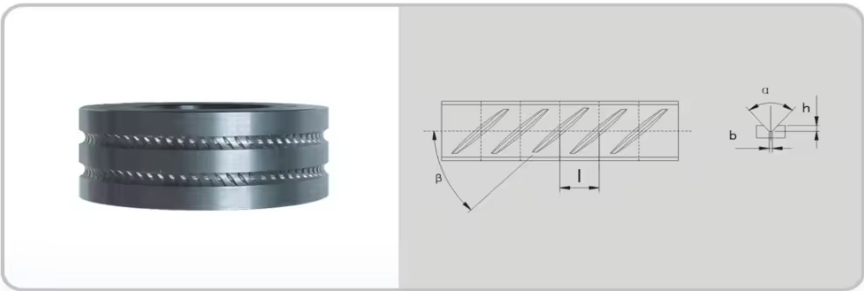

1. Excellent surface mirror finish.

2. High hardness, round HRA 87 or even to HRA91.

3. High wear resistance and corrosion resistance.

4. The service life of tungsten carbide is 50 times longer than common steel tools.

Item name :

HR45 Cemented Carbide Roller for TMT barGrade :

HR30 HR40 HR45Hardness :

84~86 HRACobalt % :

17%-23%grain size :

1.6-2.4Usage :

Hot rolling rollerLogo :

HR Carbidepackage :

standard sea worth

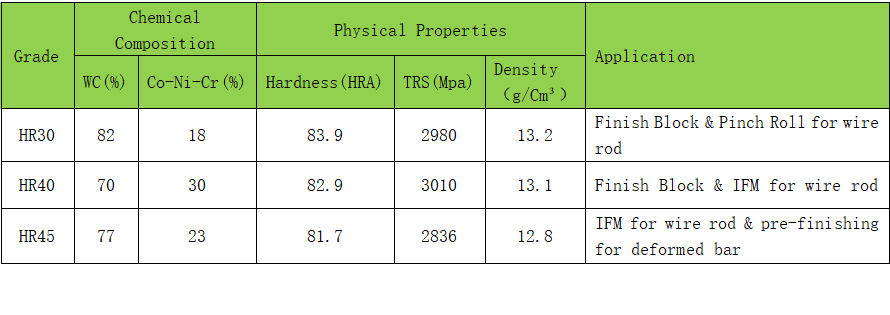

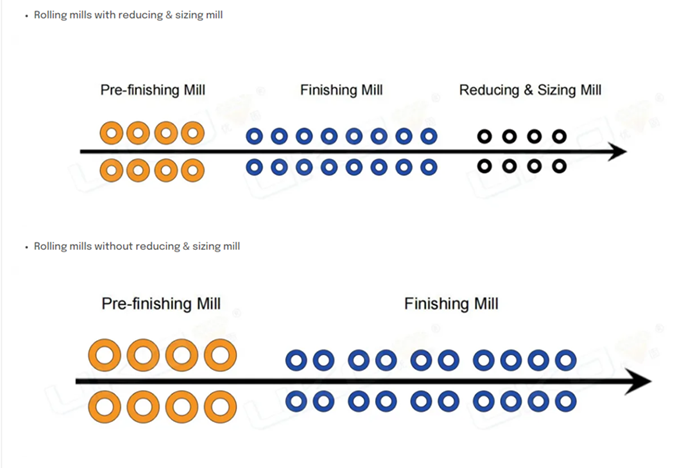

Our company independently developed carbide grades HR30 HR40 HR45 for hot rolling rollers: with high temperature resistance, high pressure resistance, high hardness, high wear resistance, efficient production and high economic benefits. The specific performance is as follows:

1. The hardness range is 82HRA-84HRA, with excellent wear resistance, and can be used for a long time without frequent replacement.

2. High shape and size accuracy, can maintain a stable shape and position, ensure the accuracy and consistency of the rolling process, and improve product quality.

3. It has excellent high temperature and high pressure resistance, can withstand high temperature and high pressure during rolling

4. Efficient production and high economic benefits

In addition, due to the high thermal conductivity and good heat dissipation effect of carbide hot rolling rollers, they are more resistant to corrosion and cold and hot fatigue than tool steel rollers.

Tags :