-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

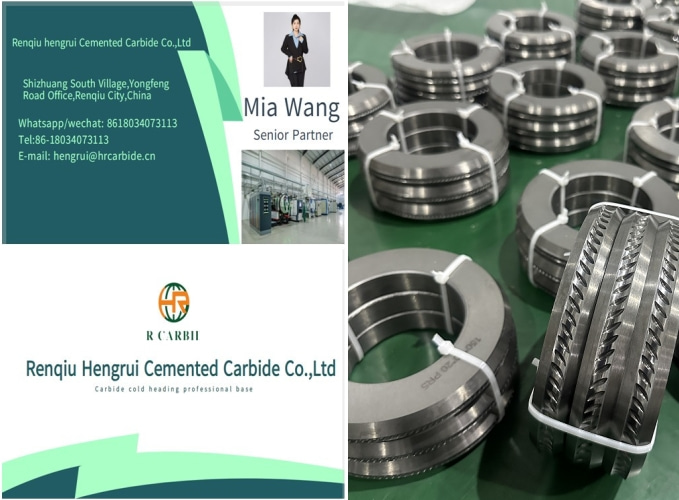

Durable tungsten carbide rolls coil for wire rod rolling: outer diameter 150mm, inner diameter 95mm, thickness 15mm

In the world of wire rod rolling, the quality and durability of the tools used are crucial. One of the tools that stands out in this industry is the tungsten carbide roller. Specifically, rollers with an outer diameter (OD) of 150 mm, an inner diameter (ID) of 95 mm, and a thickness of 15 mm have proven to be very reliable and efficient. This article takes an in-depth look at the features, benefits and applications of these durable tungsten carbide rolls, highlighting why they are the first choice for wire rod rolling.

Unparalleled durability and strength

Tungsten carbide is known for its exceptional hardness and wear resistance. This makes it an ideal material for making rolls for wire rod rolling. Tungsten carbide rolls with an outer diameter of 150 mm, an inner diameter of 95 mm and a thickness of 15 mm are designed to withstand the high pressures and temperatures involved in wire rod rolling. Their durability ensures a longer service life compared to rollers made of other materials, thus reducing replacement frequency and production line downtime. This not only increases productivity but also reduces maintenance costs, making it a cost-effective solution for wire rod rolling operations.

Precision and consistency of wire rod rolling

The accuracy of the rolls used in wire rod rolling directly affects the quality of the final product. Tungsten carbide rollers with an outer diameter of 150mm, an inner diameter of 95mm and a thickness of 15mm are engineered to provide consistent performance. Their precise dimensions ensure even pressure distribution during rolling, resulting in wire rods with consistent diameters and smooth surfaces. This level of accuracy is critical in industries where wire quality is critical, such as the manufacturing of electrical wires, automotive parts and building materials. The use of these rollers helps maintain strict quality standards, thus enhancing the reputation of the manufacturer.

Application Versatility

The versatility of tungsten carbide rolls extends their utility to a variety of wire rod rolling applications. Whether hot or cold rolled, these rolls can handle a variety of materials, including steel, copper, aluminum and other alloys. Their ability to operate efficiently under different rolling conditions makes them a versatile tool for the wire rod rolling industry. 150*90*15 Rolls with an outer diameter of 150 mm, an inner diameter of 95 mm and a thickness of 15 mm are particularly suitable for medium to large wire rod rolling operations where demand for high quality and consistent wire rod products is high. Their adaptability to different rolling processes and materials further highlights their importance in the industry.

Enhanced performance and efficiency

The performance of tungsten carbide rolls is significantly enhanced by their unique properties. Tungsten carbide's high hardness and toughness allow these TC rollers to maintain their shape and sharpness over extended periods of use. This reduces interruptions during the rolling process, thereby increasing efficiency and productivity. The rolls with an outer diameter of 150 mm, an inner diameter of 95 mm and a thickness of 15 mm are designed to minimize deformation and wear, ensuring that the rolling process remains smooth and uninterrupted. This enhanced performance means higher throughput rates and better quality wire rod products, making these rolls an indispensable asset in wire rod rolling operations.

Cost-effectiveness and long-term benefits

Investing in durable tungsten carbide rolls with an outer diameter of 150 mm, an inner diameter of 95 mm and a thickness of 15 mm can provide long-term benefits that exceed the initial cost. While the upfront investment may be higher compared to rolls made from other materials, tungsten carbide rolls last longer and require lower maintenance, resulting in significant cost savings over time. The durability and efficiency of these rollers reduces changeovers and downtime, increasing overall productivity. Additionally, the consistent quality of wire products produced using these rolls increases customer satisfaction and business opportunities.

In summary, durable tungsten carbide rolls with an outer diameter of 150 mm, an inner diameter of 95 mm and a thickness of 15 mm are an important part of the wire rod rolling industry. Its unparalleled durability, precision, versatility, enhanced performance and cost-effectiveness make it the first choice for manufacturers looking to improve the quality and efficiency of their wire rod rolling operations. By investing in these high-quality reels, manufacturers can increase productivity, reduce maintenance costs, and produce high-quality wire products that meet the stringent requirements of various industries.