-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

• The nut blank to be shaped is conveyed to the first station through the feeding device. The feeding device needs to ensure that the nut blank can enter the station accurately and stably, and generally uses a vibrating plate, conveyor belt and other methods for feeding.

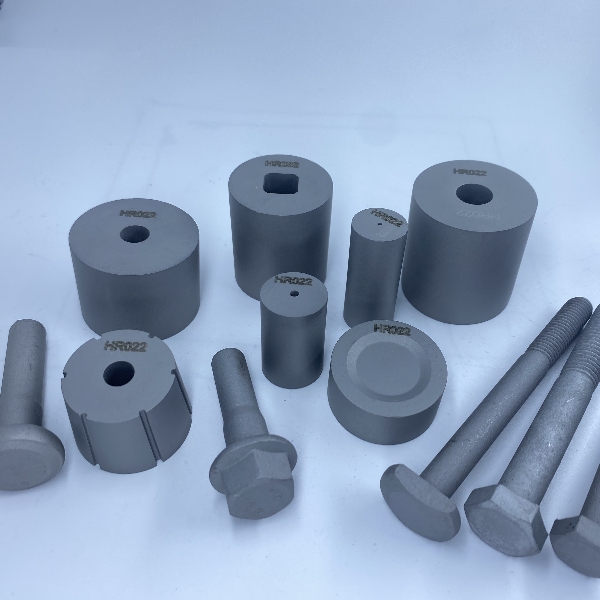

• At the first station,tungsten carbide nut forming die there is usually a positioning device to preliminarily position the nut blank to ensure its accurate position in the subsequent shaping process, such as fixing the position of the nut blank by a fixture or slot of a specific shape.

2. First shaping:

• The first shaping operation is performed at the second station. This step is mainly to make preliminary adjustments to the overall shape of the nut, remove some obvious deformations, burrs and other defects, so that the shape of the nut roughly meets the requirements.

• The shaping method may be to shape the nut blank according to the preset shape through the extrusion, stamping and other actions of the mold. The precision and strength of the mold are crucial to the shaping effect, and it needs to be designed and manufactured according to the specific specifications and requirements of the nut.

3. Intermediate treatment (may be multiple times):

• The third station usually carries out some intermediate treatment steps, carbide nut die which may vary depending on the specific process requirements of the nut. For example, if the nut needs special surface treatment, such as degreasing, rust removal, etc., the corresponding treatment may be carried out at this station; or some local fine-tuning of the nut may be carried out to further improve its shape accuracy.

• If multiple intermediate treatments are required, they may be carried out in different intermediate stations in sequence according to the order and requirements of the treatments.

4. Final shaping:

• The fourth station is the final shaping operation. This step ensures that the shape, size, accuracy and other indicators of the nut meet the design requirements. Compared with the first shaping, the strength and accuracy control of the final shaping will be more stringent, and higher precision molds and more accurate processing parameters may be used.

• In the final shaping process, the key parts of the nut, such as the threaded part and the hexagonal head, will be finely processed and adjusted to ensure the quality and performance of the nut.

5. Quality inspection and discharge:

• Quality inspection is carried out at the fifth station. The inspection contents include the dimensional accuracy, shape accuracy, thread quality and other aspects of the nut, which can be measured by measuring tools, machine vision inspection and other methods.

• For nuts that pass the inspection, they are transported to the finished product collection area through the discharging device; for unqualified nuts, they are classified and collected for subsequent rework or other processing.

Tags :