-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

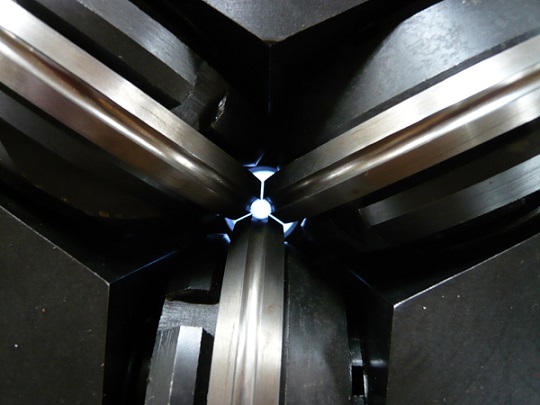

The rolls continuously plastically deform the main workpieces and tools on the rolling mill. Carbide rollers consist of a roller body, a roller neck and a shaft head. The roll body is the middle part of the roll that actually participates in rolling metal. It has a smooth cylindrical or grooved surface.

The carbide roll neck is installed in the bearing, and the rolling force is transmitted to the frame through the bearing housing and the hold-down device. The shaft end of the transmission end is connected to the gear seat through the connecting shaft and transmits the rotation torque of the motor to the roller. The rollers can be arranged into two, three, four or more carbide rollers in the roller frame. A brief history of the development of cemented carbide rolls.

With the advancement of metallurgical technology and the development of rolling equipment, the types and manufacturing processes of cemented carbide rolls have continued to develop. Low-strength gray cast iron rolls were used in the rolling of soft non-ferrous metals in the Middle Ages. In the mid-18th century, Britain mastered the production technology of chilled cast iron rollers for rolling steel plates. In the second half of the 19th century, advances in European steelmaking technology required the rolling of larger tonnage steel ingots, regardless of whether the strength of gray cast iron or chilled cast iron rolls did not meet the requirements. Carbon steel is 0.4% to 0.6% of ordinary cast steel rolls. The appearance of heavy-duty forging equipment further enhances the toughness of the forged rolls of this composition. The introduction of alloying elements and heat treatment in the early 20th century significantly improved the wear resistance and toughness of cast and forged hot and cold rolls. The addition of molybdenum to cast iron rolls used for hot rolled strip improves the surface quality of the rolled strip. Rinsing composite castings significantly increases the core strength of the casting rolls. After World War II, alloying elements were widely used in rolls. After rolling equipment size, continuity, high speed, automation development, increased rolling material strength and increased resistance to deformation, this places higher requirements on roll performance. the result of. During this period, semi-steel rolls and ductile iron rolls appeared. After the 1960s, powdered tungsten carbide rollers were successfully developed. The centrifugal casting technology and differential heat treatment technology for rolls that were widely promoted in Japan and Europe in the early 1970s significantly improved the overall performance of strip rolls. Composite high chromium cast iron rolls have also been successfully used in hot strip mills. During the same period, Japan used forged white iron and semi-steel coils. In the 1980s, Europe introduced cold rolling rolls using high-chromium steel rolls and ultra-deep hardened layers, as well as special alloy cast iron rolls for finishing small steel and wire rods. The development of modern steel rolling technology has led to the development of higher performance rolls. Cores produced by centrifugal casting and new composite methods such as continuous casting composite method (CPC method), spray deposition method (Osprey method), electroslag welding method and hot isostatic pressing method are strong and tough forged steel or ductile iron cast iron. Composite high-speed steel rollers and cermet rollers are used in new generation profile, wire rod and strip rolling mills in Europe and Japan respectively.