-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

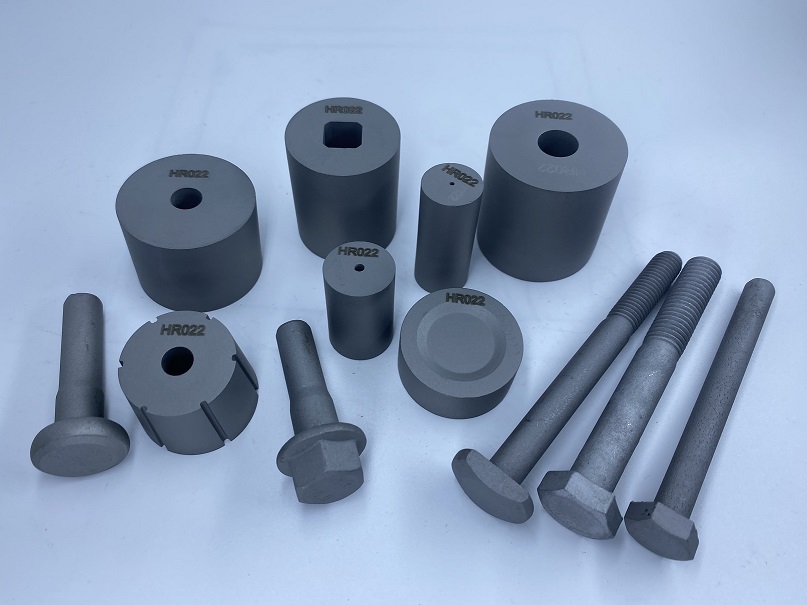

Tungsten carbide alloy is mainly made of tungsten carbide and binder cobalt.

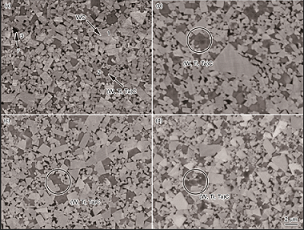

From the mechanical property results of each sample, it can be seen that the prepared cemented carbide blocks with different WC grain sizes have excellent comprehensive mechanical properties. The Vickers hardness (HV:0) values are all over 16 000MPa, and the Vickers hardness (HV:0) of the sample prepared by direct SPS sintering of 0.2 μm WC/0.8 μm Co mixed powder reaches 17460MPa. The hardness decreases with increasing WC grain size. Fracture toughness values increased with increasing WC grain size, with the highest value reaching 14.00 MPa:m12. It can be seen from the hardness and toughness values that there is a certain relationship between hardness and toughness and WC grain size, while strength is not only related to WC grain size, but more importantly, has an important relationship with the preparation process. It can be seen from the tensile strength values of each sample that the tensile strength value increases as the WC grain size increases. In addition, it can be seen that the tensile strength of SPS-sintered tungsten carbide samples after vacuum pretreatment is greater than that of direct SPS-sintered tungsten carbide samples. Among them, the tensile strength value of the sample prepared from 0.2 μm WC/0.8 μm Co mixed powder increased by 34.4%, while the tensile strength value of the sample prepared from 0.8 μm WC/0.8 μm Co mixed powder increased by 15.2%. This shows that the use of vacuum pretreatment process can greatly improve the tensile strength of cemented carbide while maintaining high hardness and toughness.