-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

Tungsten-cobalt alloys are divided into three categories: high cobalt (20% to 30%), medium cobalt (10% to 15%) and low cobalt (3% to 8%). The performance of tungsten-cobalt cemented carbide is one of the important factors.

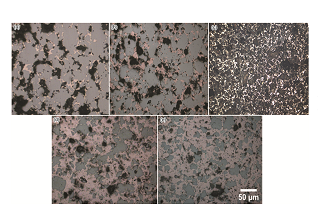

The control of alloy composition, structure and production quantity is one of the important factors. Normal tungsten-cobalt cemented carbide is related to the manufacturing process. The most important factors are: the composition of the bonding metal and the two phases of WC and y. The carbon content determines whether the third content will appear in the structure; the particle size and distribution of WC; the carbon content; the composition of the additive phase graphite or knife phase The key factors, which in turn are strongly affected by wC and cobalt powder neutralization content, as well as oxygen and carbon content that affect alloy phase composition, WC grain size and densification, wet grinding conditions, dewaxing, pre-sintering and sintering conditions Various process factors.

In the production process of tungsten-cobalt cemented carbide, carbon content affects it. The control of WC grain size in the alloy is another important factor, which seriously affects the alloy properties, which in turn is strongly affected by the original powder particle size, size, distribution, wet grinding conditions and sintering conditions; alloy densification is the most important factor in alloy properties. Important sign: Any structural defects will cause a significant reduction in alloy performance, which is strongly affected by the oxygen and carbon content of the original powder, wet grinding conditions, and pre-sintering and sintering conditions.