-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

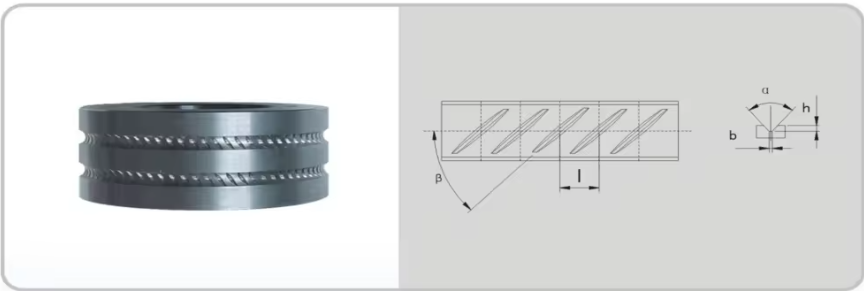

Carbide rolls, also known as tungsten carbide rolls, have excellent performance, stable quality, high product processing precision, good wear resistance and high impact resistance. Carbide rolls include rolls made of tungsten carbide, cobalt, nickel and other materials using powder metallurgy methods.

Carbide rolls are available in two types: integral and combined. Our company independently researches and develops carbide grades HR30 HR40 HR45 for hot rolling rolls: it has the advantages of high temperature resistance, high pressure resistance, high heat resistance, high wear resistance, efficient production and high economic benefits.

The specific performance is as follows: 1. The hole diameter range is 82HRA-84HRA, which has good wear resistance and can be used for a long time without replacing the wall. 2. It has high shape and size accuracy, can maintain stable shape and position, ensure the accuracy and consistency of the rolling process, and improve product quality.

3. It has good high temperature and high pressure resistance and can withstand the high temperature and high pressure during the rolling process to ensure the smooth progress of the production process. The thickness of the steel plate changes very little with the temperature. The value of the steel plate at 700℃ is high speed. Steel plate 4 times. 4. Production and high economic benefits: Carbide hot rolling rollers can improve production efficiency and product quality, reduce scrap rates and production costs, and bring higher economic benefits to enterprises. In addition, due to the high thermal conductivity and good cooling effect of cemented carbide hot rolling rollers, they are more resistant to corrosion and thermal fatigue than tool steel rollers