-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

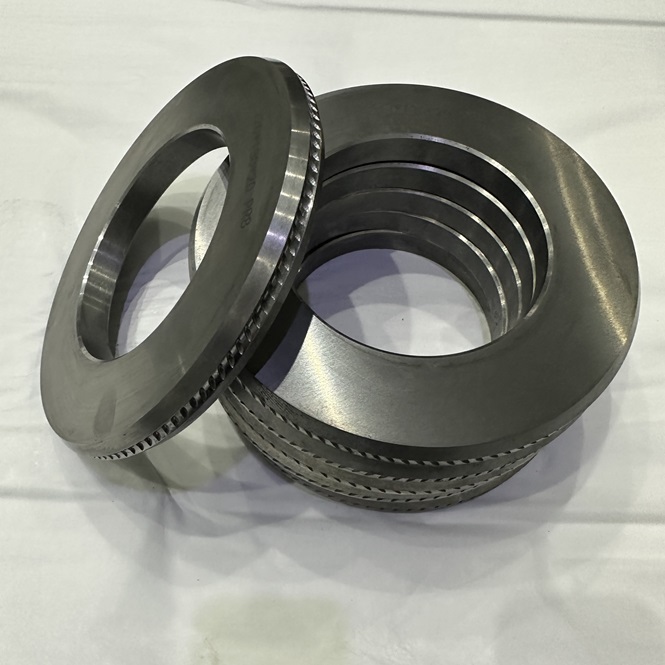

What is about tungsten carbide roller?

Tungsten carbide cold roller are specialized tools used cold rolling mills to and shape metal products Cold rolling is a metalworking process which metal is passed through 3 pieces of rollers at room temperature to reduce its thickness and improve its surface finish.

TC roller are highly efficient and durable due to the exceptional hardness and wear resistance of tungsten carbide. Tungsten carbide is a composite material made of tungsten carbide particles (hard phase) embedded in a metal matrix (binder phase), typically cobalt or nickel. This combination results in a material with excellent hardness, strength, and resistance to wear and deformation.

The tungsten carbide cold rollers are designed to withstand the high compressive forces and abrasion encountered during cold rolling operations. They are typically used for rolling various types of materials such as steel, aluminum, copper, and alloys. The precise profile and surface texture of the rollers determine the final shape and surface finish of the rolled product.

YG15 cemented carbide rolls offer several advantages over conventional rollers made of steel or other materials. These advantages include improved dimensional accuracy, extended roller life, reduced downtime for roller replacement, and enhanced surface finish of the rolled product.

Overall, tungsten carbide cold rollers play a crucial role in the cold rolling process by ensuring efficient and high-quality metal forming operations.