-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

Hot rolling is a metalworking process that involves heating a metal billet or slab to high temperatures and then passing it through a pair of rolls to reduce its thickness and shape it into various forms such as sheets, plates, or bars. Here is a general overview of the hot rolling process:

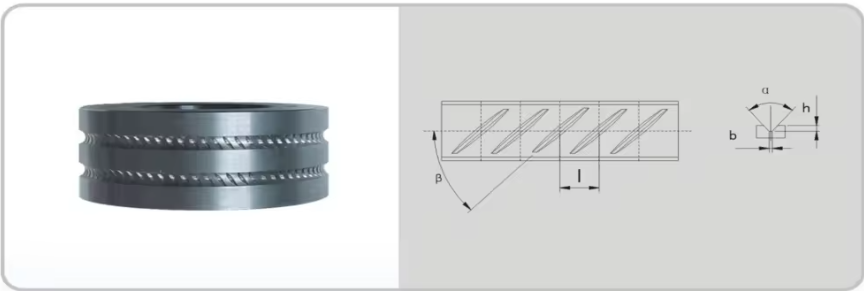

Hot Rolling Roller

Heating: The process begins with heating the metal to its rolling temperature, which is typically above the re-crystallization temperature but below the melting point. The heating is usually done in a.

Descaling: After heating, the metal surface often contains scales and oxides. These impurities are removed through descaling, which can be done mechanically or chemically. Mechanical descaling involves passing the metal through abrasive rollers or brushes, while chemical descaling uses acids or pickling solutions.

Reheating (optional): In some cases, the metal may need to be reheated to maintain the desired rolling temperature throughout the process. This can be done using induction heaters or other heating methods.

Rolling: The heated metal is then fed into a rolling mill, which consists of a pair of rotating rolls. The rolls exert pressure on the metal as it passes through, causing it to deform and reduce in thickness. The rolls may have different profiles and sizes to achieve specific shapes and dimensions

Reduction and shaping: As the metal passes through the rolls, it undergoes plastic deformation, which reduces its thickness and changes its shape. The metal may be rolled multiple times, gradually reducing its thickness with each pass, until the desired dimensions are achieved.

Cooling: Once the metal has been rolled to the desired shape and thickness, it is often cooled using water or air jets to prevent excessive heat buildup and to stabilize its micro-structure.

Further processing: After hot rolling, the metal may go through additional processes, such as annealing, quenching, or surface treatments, depending on the desired properties and applications of the final product.

Hot rolling is commonly used in the production of steel, aluminum, copper, and other metals and alloys. It allows for the fabrication of a wide range of products used in various industries, including construction, automotive, aerospace, and manufacturing.