-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

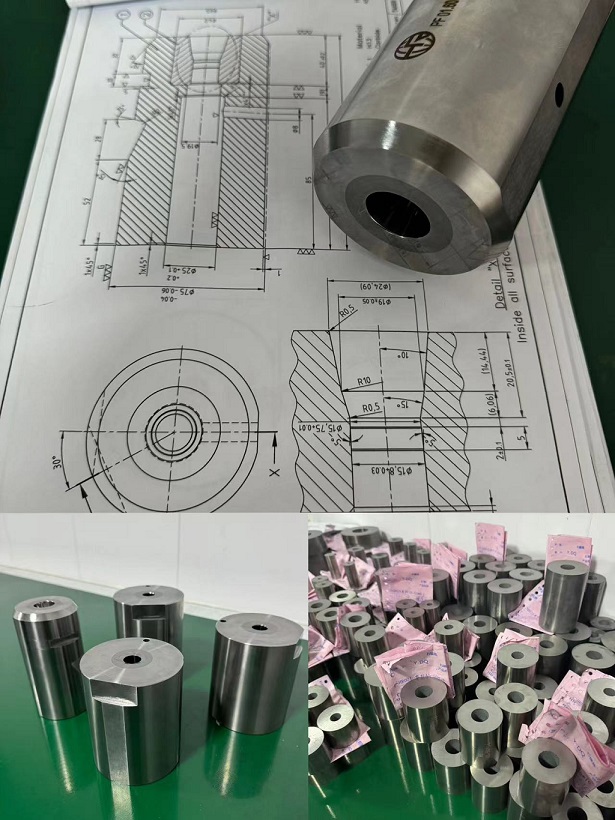

When manufacturing a die, a die that uses a hard tungsten material with high hardness, high strength, high wear resistance, corrosion resistance, high temperature resistance and a small expansion coefficient as a punch and a concave die is called a hard alloy die. The main material used for the punch and concave die is a tungsten carbide hard alloy.

When manufacturing a die, a die that uses a hard alloy material with high hardness, high strength, high wear resistance, corrosion resistance, high temperature resistance and a small expansion coefficient as a punch and a concave die is called a tungsten carbide hard alloy die. The main material used for the punch and concave die is a tungsten carbide hard alloy die.

The structure of a hard alloy die is basically the same as that of a steel die. It can be made into a single-process die, a compound die and a continuous carbide die. However, because hard alloy itself is brittle, it is best not to make the hard alloy cutting edge bear unilateral force during punching. The die structure used in mass production is mostly a continuous die structure.

Hard alloy dies mostly use a floating die handle structure to avoid the influence of the precision of the press on the stamping process during stamping.

The die frame used for hard alloy dies should have sufficient rigidity. The template should be 5 ~ 10mm thicker than the general steel die template, and is usually made of 45# steel, HRC38 ~420