-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

The material selection of cold heading molds should consider their service life, wear resistance, strength and toughness. The following are some materials suitable for cold heading molds:

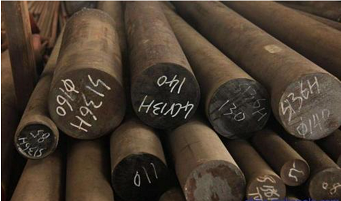

1. High alloy mold steel: such as Cr5Mo1V, Cr12, Cr12MoV, 7CrMo2V2Si, etc. These materials have high strength, high hardness and excellent wear resistance.

2. High-speed steel: such as W6Mo5Cr4V2, W18Cr4V, etc., and powdered high-speed steel. These materials have good wear resistance and toughness.

3. Steel-bonded cemented carbide or cemented carbide with high cobalt content: These materials are suitable for high-strength and high-wear-resistant applications.

4. New steel types: such as 65Cr4W3M02VNb (65Nb), 7Cr7M03V2Si (LD) 6Cr4M03Ni2WV (CG2), etc. These materials can increase the service life of the mold county.

5. SKD61 mold steel: This is an imported high-grade hot work alloy tool steel with good toughness and high temperature fatigue resistance, and is suitable for long-term work at high temperatures.

6. Carbide tungsten steel: materials such as YG20C and YG25 have high hardness, good wear resistance and long service life. With the continuous improvement of cemented carbide process technology, many new carbide grades have appeared on the market.

When selecting cold heading mold materials, you also need to consider the production batch size of the workpiece, the material of the workpiece to be punched, and the heat treatment requirements.