-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

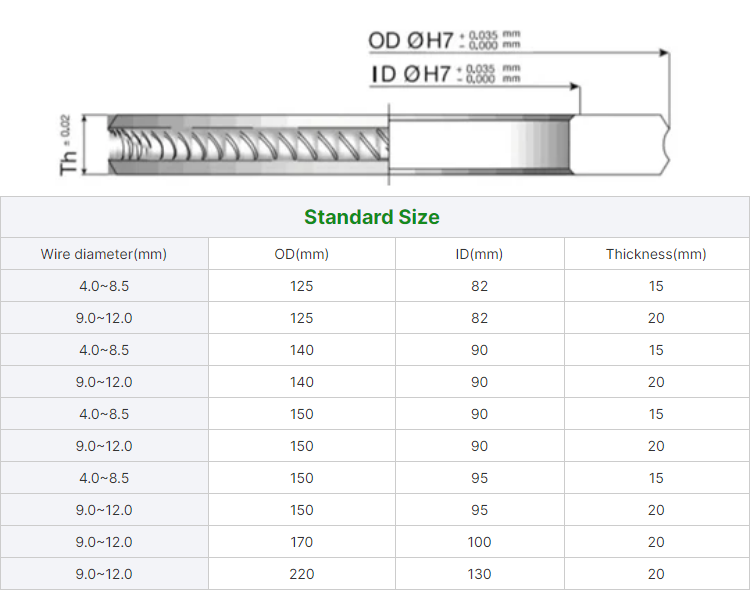

Carbide roll rings (also called tungsten carbide roll rings) refer to rolls made of tungsten carbide and cobalt using powder metallurgy methods. It has superior performance, stable quality, high product processing precision, good wear resistance and high impact resistance.

Item name :

Tungsten carbide cold heading blankGrade :

YG15 YGR30Hardness :

HRA86Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

TUNGSTEN CARBIDE ROLLERLogo :

HENGRUIpackage :

cartonDetailed Description:

As the market competition for steel product quality and price becomes increasingly fierce, the rolling speed of rolling mills is continuously increased; at the same time, how to reduce the number of shutdowns of the rolling mill and further improve the effective operating rate of the rolling mill, and the use of roll materials with higher rolling life is One of the important means to achieve this goal

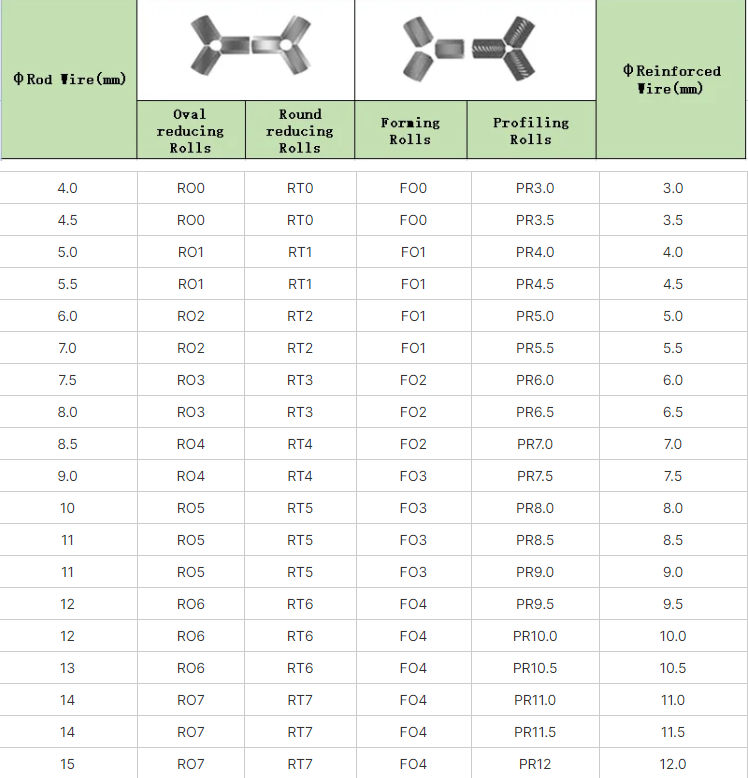

The contour size design of the roll includes parameters such as roll shape, roll diameter, circumferential speed, and pressure angle. When formulating, it should be comprehensively considered based on factors such as the type of metal material processed, processing technology, processing requirements, and equipment capabilities. Roller profile design is one of the important process parameters, which directly determines the pressing form and processing efficiency of metal materials.

Tags :