-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

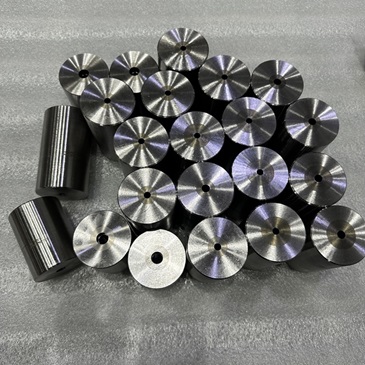

Dehli Best Sale Tungsten Carbide Cold Forging Pallets GT55 for Fastener Mold

The selection of a suitable grade for a tungsten carbide cold heading die depends on several factors, such as the type of material being formed, the complexity of the part, the required surface finish, and the expected production volume.

Hardness: 81.7HRA, 82.7 HRA 83.7HRA, 84.7HRA

Item name :

Delih Best Sale Tungsten Carbide Cold Forging Pallets GT55 for Fastener MoldGrade :

HR00 HRS ZHDHardness :

HRA82~85Cobalt % :

18~25%grain size :

0.6~2.6umUsage :

Cold heading Dies Hot Forging DieLogo :

HENGRUIpackage :

bubble plastic bag +plastic casesOther main products of HengRui Carbide.

Detailed Description:

Hardness: Cold heading dies require high hardness to withstand the repeated impact and wear during the cold forming process. The hardness of tungsten carbide is typically measured on the Rockwell scale, such as Rockwell A (Rc) or Rockwell C (Rc). Higher hardness values generally indicate better resistance to wear

If the selected grade is prone to early cracking and damage during use, a grade with higher toughness should be selected; if the selected grade is prone to early wear and damage during use, a grade with higher hardness and good durability should be selected.

The following grades: YG15C, YG18C, YG20C, YG22C, YG25C from left to right, the hardness decreases, the wear resistance decreases, and the wear resistance increases; vice versa.

| GRADE | Composition | Carbide Grain Size |

Properties | ||||||||||

| Binder | WC+others | Density | Hardness | Hardness | TRS | ||||||||

| (±0.5%) | (±0.5%) | ISO Classification |

g/cm³ | HRA±0.3 | HRC | MPA | |||||||

| HV30 | |||||||||||||

| ZHD82 | 27 | 73 | 2.6 | 13.3 | 81.7 | 61 | 2713 | ||||||

| ZHD82A | 25 | 75 | 2.6 | 13.3 | 82.7 | 63 | 2723 | ||||||

| ZHD84 | 23 | 77 | 2.6 | 13.52 | 83.7 | 64.5 | 2800 | ||||||

| YG20C | 23 | 77 | 2.6 | 13.81 | 83.7 | 64.5 | 2800 | ||||||

| ZHD86 | 21 | 79 | 2.6 | 13.52 | 84.7 | 66 | 2976 | ||||||

| HR001 | 23.5 | 76.5 | 2.6 | 13.09 | 83 | 63.5 | 2700 | ||||||

| HR002 | 25 | 75 | 1.4 | 12.9 | 84 | 65.3 | 3305 | ||||||

| HR003 | 24 | 76 | 1.2 | 13.01 | 85 | 66.6 | 3550 | ||||||

| HR004 | 23 | 77 | 1.4 | 13.04 | 85 | 66.6 | 3500 | ||||||

| HR005 | 10 | 90 | 1.2 | 14.46 | 89.5 | 75.1 | 3700 | ||||||

| HR006 | 23 | 77 | 2.8 | 13.24 | 82 | 61.5 | 2700 | ||||||

| HR007 | 16 | 84 | 1.6 | 13.8 | 87 | 70.4 | 3700 | ||||||

| HR009 | 17 | 83 | 1.4 | 13.73 | 86 | 67.9 | 3500 | ||||||

| HR011 | 12.5 | 87.5 | 1.4 | 14.28 | 88 | 72.2 | 3600 | ||||||

| HR021 | 18.5 | 81.5 | 2.8 | 13.57 | 84.5 | 65.9 | 2900 | ||||||

| HR022 | 19 | 81 | 2.4 | 13.5 | 85 | 66.6 | 3400 | ||||||

| HR023 | 15 | 85 | 2.6 | 13.79 | 86 | 67.9 | 3100 | ||||||

| HR029 | 26 | 74 | 3.2 | 12.92 | 80.5 | 59 | 2900 | ||||||

| HR012 | 25 | 75 | 1.2 | 13.17 | 84 | 65.3 | 3000 | ||||||

| HRS1 | 19.5 | 80.5 | 2.4 | 13.26 | 83.5 | 64..5 | 2900 | ||||||

Q1: Are you a factory or a trading company?

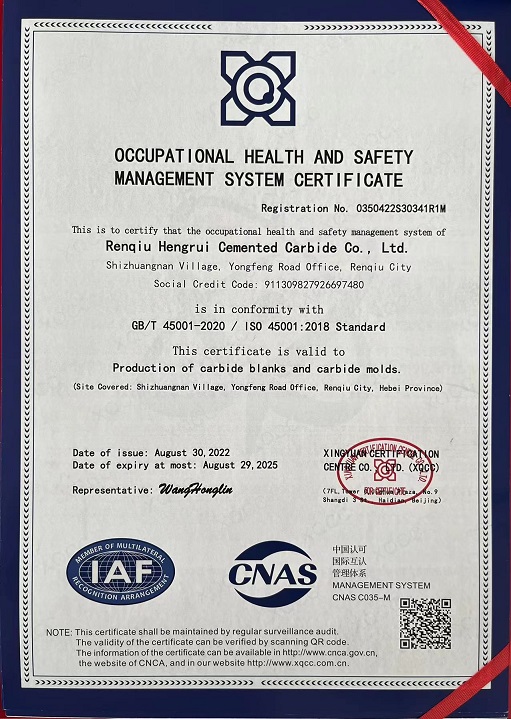

We are a factory with 25 years of production experience.

Q2: Where is your factory located?

We are located in Renqiu City, Hebei Province, adjacent to Beijing

Q3: How can we trust your company?

We support Alibaba Trade Insurance, 100% product quality guarantee, 100%

On-time shipping protection, 100% payment protection on your covered amount.

Q4: What is your delivery time?

For normal types for which we have molds, it will take 7-15 working days after payment is received.

Tags :