-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

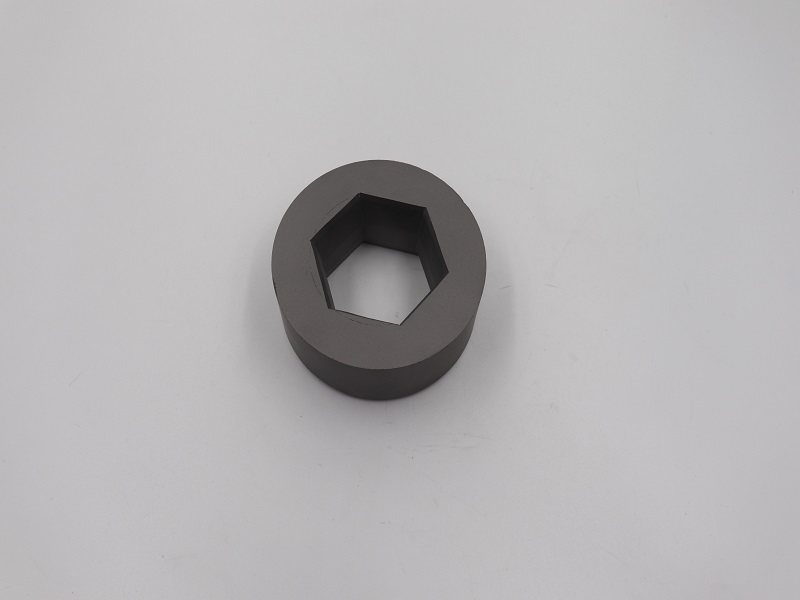

High Hardness Tungsten carbide Hot forging die for hexagonal nuts

are widely used in hex steel nut production.

we recommend HRS6 HRS7 Grade

Hardness 83.5-84.5HRA ,with good toughness and wear resistance,HRS6 is a good choice for

drywall screws, self-taping screw and hex head screws below M16

Used in reduction mold, Hex group forming mold, nut mold and lasering punches.

Item name :

High Hardness Tungsten carbide Hot forging die for hexagonal nutsGrade :

HRS6 HRS7Hardness :

83.5-84.5 HRACobalt % :

25%grain size :

1.4Usage :

black carbon steel screw,nails and nutsLogo :

customizedpackage :

standard seawoth=harm proof package or as your requirement

High Hardness Tungsten carbide Hot forging die for hexagonal nuts

widely used in steel fastener industries

With its high hardness, toughness and good wear resistance, it is suitable for

making the steel rods and wires into different shaped screws, bolts and nuts.

HengRui has developed 48 grades independently including ZHD series and HR series, including carbide for carbon steel products, carbide for cold heading/cutting/punching /stamping/rolling dies, carbide for hot forging molds, non magnetic carbides, high density carbide, etc.

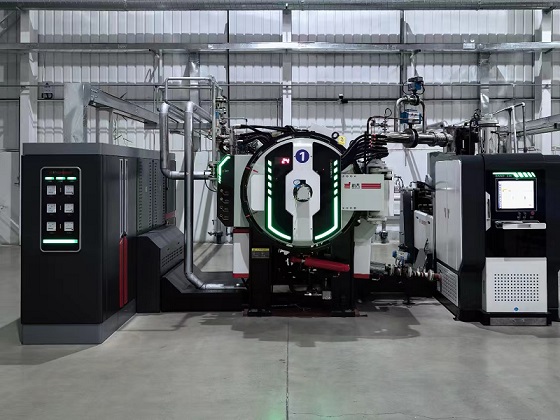

Hengrui adopts the most advanced equipment in production , this mostly guarantee the product properties stable and save the labor ,thus decreasing the cost, making the price competitive for customers.

1.Experienced

We have specialized in carbide production since 2006,having 18 years' accumulation of grade research production experience.

2.Professional

We have developed 48 grades independently ,suitable for different working conditions according to the feedback of market.

3.Capable

We adopt the most advanced equipment and 7S system management to control the products quality and cost.

4.Reliable

We are professional in the grade research and grade selection for the costumers, helping you find the most suitable and durable grades.

5.Serious

We supply free sample for customers and after sales service will be followed.

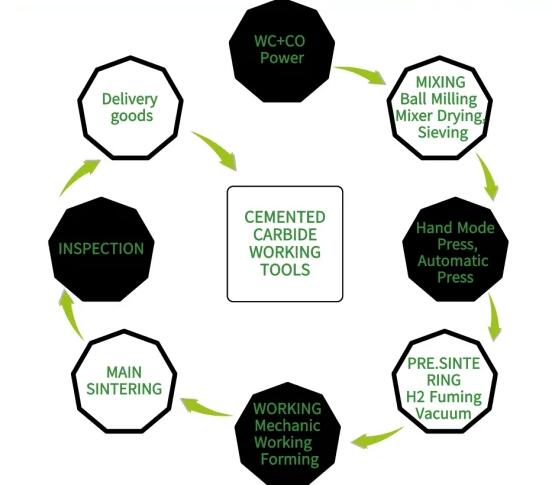

Formula→ Wet Ball Mill →Mixed WC and Co Powder→ Pressing→ HIP Sintering →Testing →Packing

Q1: What is the warranty of the product?

A1: If any quality problems occur on our side during this period, we will find the best way to reduce your losses, your satisfaction is our primary purpose!

Q2: Do you provide free samples?

A2: Yes, you can get free samples for testing when you pay the shipping cost.

Q3: What is your minimum order requirement?

A3: We hope you are clear about your quantity, if you are not clear, we will indicate the minimum order quantity of each item in the quotation. We welcome samples and trial orders. If the quantity of a single product does not reach the minimum order quantity, the price will be based on the sample price.

Q4: What is the delivery time of your products?

A4: It depends on stock availability. If the required item is in stock, the delivery time will be within 7 working days, but if it is not in stock, the delivery time will be around 7-30 working days.

Q5: What types of products do you supply?

A5: We can produce both standard production and special production. According to your requirements, drawings and samples.

Tags :