-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

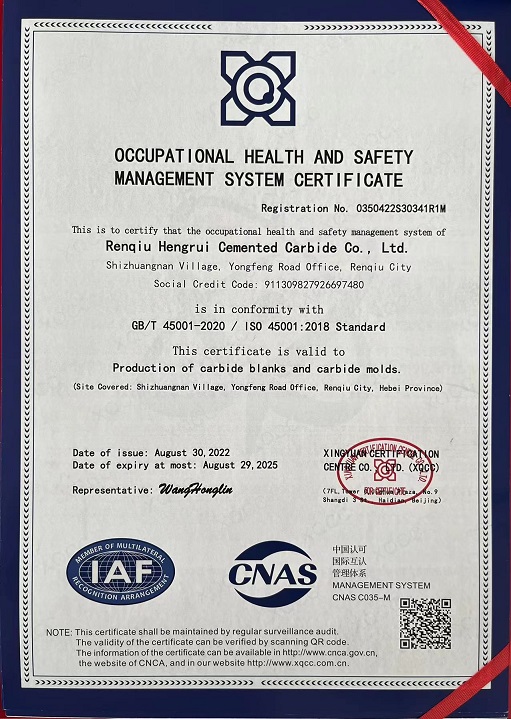

All use HIP sintering technology and are managed in strict accordance with the ISO9001 quality management system; the main products include cold heading dies, powder metallurgy dies, drawing dies, high specific gravity alloys, special molds, carbide spherical mold tanks, carbide nozzles, Carbide plates, high temperature resistance, corrosion resistance, non-magnetic alloy materials, carbide rollers, valve seats, valve cores, etc.; products ranging from 1-2 grams to 200 kilograms are widely used in high-speed rail, aviation, It is engaged in many fields such as shipyard manufacturing, tunnel boring, oil exploration, precision electronics, mobile phone parts, automobiles and military industry.

Item name :

Tungsten Carbide Heading Die Cemented Carbide Forging DieGrade :

G40 G50 G45Hardness :

HRA82~88Cobalt % :

18~25%grain size :

0.6~2.6umUsage :

Cold heading Hot forgingLogo :

HENGRUIpackage :

cartonDetailed Description:

Cold heading involves forming a piece of metal by applying pressure beyond its elastic limit. It is most commonly used on steel and stainless steel, which are popular for their strength and corrosion resistance. This process results in a dense product with an excellent surface finish. Some advantages of cold heading include a more uniform surface finish and fewer metal inclusions. While this process involves a higher level of detail than hot heading, there is minimal waste. Therefore, it is often the first choice of many companies and manufacturers

| GRADE | Composition | Carbide Grain Size |

Properties | ||||||||||

| Binder | WC+others | Density | Hardness | Hardness | TRS | ||||||||

| (±0.5%) | (±0.5%) | ISO Classification |

g/cm³ | HRA±0.3 | HRC | MPA | |||||||

| HV30 | |||||||||||||

| ZHD82 | 27 | 73 | 2.6 | 13.3 | 81.7 | 61 | 2713 | ||||||

| ZHD82A | 25 | 75 | 2.6 | 13.3 | 82.7 | 63 | 2723 | ||||||

| ZHD84 | 23 | 77 | 2.6 | 13.52 | 83.7 | 64.5 | 2800 | ||||||

| YG20C | 23 | 77 | 2.6 | 13.81 | 83.7 | 64.5 | 2800 | ||||||

| ZHD86 | 21 | 79 | 2.6 | 13.52 | 84.7 | 66 | 2976 | ||||||

| HR001 | 23.5 | 76.5 | 2.6 | 13.09 | 83 | 63.5 | 2700 | ||||||

| HR002 | 25 | 75 | 1.4 | 12.9 | 84 | 65.3 | 3305 | ||||||

| HR003 | 24 | 76 | 1.2 | 13.01 | 85 | 66.6 | 3550 | ||||||

| HR004 | 23 | 77 | 1.4 | 13.04 | 85 | 66.6 | 3500 | ||||||

| HR005 | 10 | 90 | 1.2 | 14.46 | 89.5 | 75.1 | 3700 | ||||||

| HR006 | 23 | 77 | 2.8 | 13.24 | 82 | 61.5 | 2700 | ||||||

| HR007 | 16 | 84 | 1.6 | 13.8 | 87 | 70.4 | 3700 | ||||||

| HR009 | 17 | 83 | 1.4 | 13.73 | 86 | 67.9 | 3500 | ||||||

| HR011 | 12.5 | 87.5 | 1.4 | 14.28 | 88 | 72.2 | 3600 | ||||||

| HR021 | 18.5 | 81.5 | 2.8 | 13.57 | 84.5 | 65.9 | 2900 | ||||||

| HR022 | 19 | 81 | 2.4 | 13.5 | 85 | 66.6 | 3400 | ||||||

| HR023 | 15 | 85 | 2.6 | 13.79 | 86 | 67.9 | 3100 | ||||||

| HR029 | 26 | 74 | 3.2 | 12.92 | 80.5 | 59 | 2900 | ||||||

| HR012 | 25 | 75 | 1.2 | 13.17 | 84 | 65.3 | 3000 | ||||||

| HRS1 | 19.5 | 80.5 | 2.4 | 13.26 | 83.5 | 64..5 | 2900 | ||||||

Tags :