-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

1. Cold heading is carried out under normal temperature conditions. Cold heading can improve the mechanical properties of metal parts.

2. Cold heading forging process can improve material yield. It is a pressure processing method based on plastic deformation, which can achieve less or no cutting processing. Generally, the material utilization rate is above 85%, and can reach as high as above 99%.

3. Can improve production efficiency. The time and process of deforming metal products are relatively short, especially when parts are processed on multi-station forming machines...

4. The cold heading and forging process can improve the surface roughness of the product and ensure product accuracy.

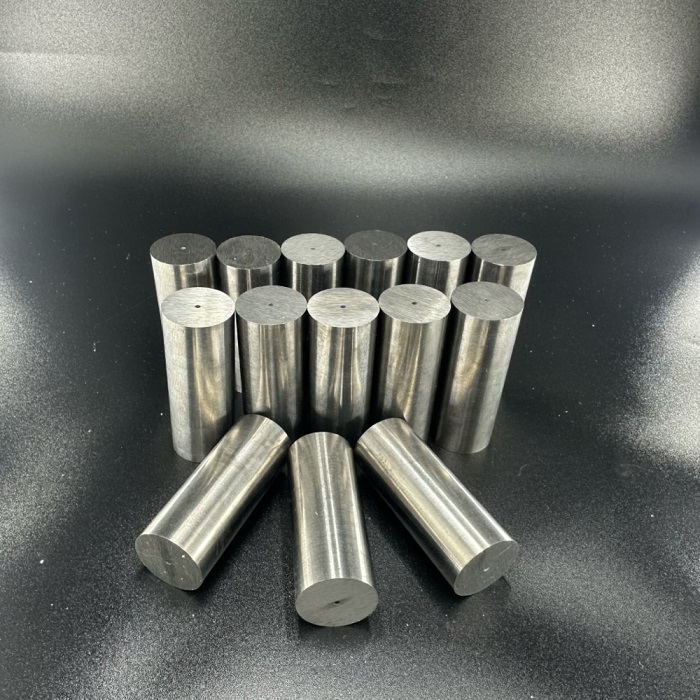

Item name :

Tungsten Carbide Heading DieGrade :

G40 G50 G45Hardness :

HRA82~88Cobalt % :

18~25%grain size :

0.6~2.6umUsage :

Cold heading deisLogo :

HENGRUIpackage :

cartonDetailed Description:

| GRADE | Composition | Carbide Grain Size |

Properties | ||||||||||

| Binder | WC+others | Density | Hardness | Hardness | TRS | ||||||||

| (±0.5%) | (±0.5%) | ISO Classification |

g/cm³ | HRA±0.3 | HRC | MPA | |||||||

| HV30 | |||||||||||||

| ZHD82 | 27 | 73 | 2.6 | 13.3 | 81.7 | 61 | 2713 | ||||||

| ZHD82A | 25 | 75 | 2.6 | 13.3 | 82.7 | 63 | 2723 | ||||||

| ZHD84 | 23 | 77 | 2.6 | 13.52 | 83.7 | 64.5 | 2800 | ||||||

| YG20C | 23 | 77 | 2.6 | 13.81 | 83.7 | 64.5 | 2800 | ||||||

| ZHD86 | 21 | 79 | 2.6 | 13.52 | 84.7 | 66 | 2976 | ||||||

| HR001 | 23.5 | 76.5 | 2.6 | 13.09 | 83 | 63.5 | 2700 | ||||||

| HR002 | 25 | 75 | 1.4 | 12.9 | 84 | 65.3 | 3305 | ||||||

| HR003 | 24 | 76 | 1.2 | 13.01 | 85 | 66.6 | 3550 | ||||||

| HR004 | 23 | 77 | 1.4 | 13.04 | 85 | 66.6 | 3500 | ||||||

| HR005 | 10 | 90 | 1.2 | 14.46 | 89.5 | 75.1 | 3700 | ||||||

| HR006 | 23 | 77 | 2.8 | 13.24 | 82 | 61.5 | 2700 | ||||||

| HR007 | 16 | 84 | 1.6 | 13.8 | 87 | 70.4 | 3700 | ||||||

| HR009 | 17 | 83 | 1.4 | 13.73 | 86 | 67.9 | 3500 | ||||||

| HR011 | 12.5 | 87.5 | 1.4 | 14.28 | 88 | 72.2 | 3600 | ||||||

| HR021 | 18.5 | 81.5 | 2.8 | 13.57 | 84.5 | 65.9 | 2900 | ||||||

| HR022 | 19 | 81 | 2.4 | 13.5 | 85 | 66.6 | 3400 | ||||||

| HR023 | 15 | 85 | 2.6 | 13.79 | 86 | 67.9 | 3100 | ||||||

| HR029 | 26 | 74 | 3.2 | 12.92 | 80.5 | 59 | 2900 | ||||||

| HR012 | 25 | 75 | 1.2 | 13.17 | 84 | 65.3 | 3000 | ||||||

| HRS1 | 19.5 | 80.5 | 2.4 | 13.26 | 83.5 | 64..5 | 2900 | ||||||

Renqiu Hengrui Cemented Carbide Co., Ltd. is a domestic high-tech enterprise integrating research, development, production and sales of medium and high-end cemented carbide products. It is also a professional cemented carbide manufacturer in Guangdong Province and a member of Hebei Province. Weight Enterprise, a small and medium-sized technology company, has passed ISO9001, quality management and other system certifications.

Q1: What is the Warranty for the products?

A1: We use the best and suitable material to fit your request and market, We own high precision grading machine to control geometry dimensions and guarantee the lifetime of our products, which can satisfy every working condition. If any quality problems on our side occurred in this period , we will find a best way to reduce your loss, your satisfaction is our first purpose!

Tags :