-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

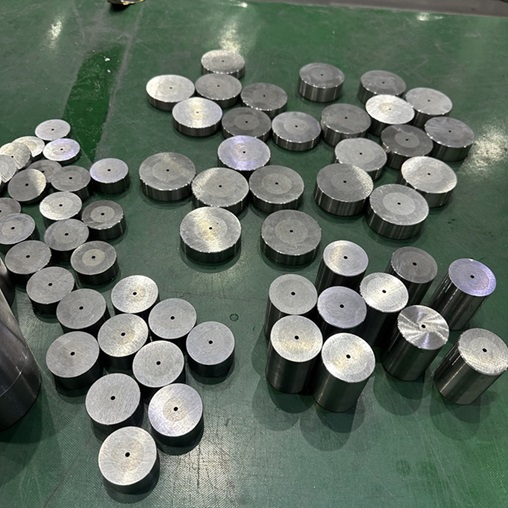

Tungsten Carbide Cold Heading Die for Multi Station Cold Heading Machine Main Die

Tungsten carbide cold heading dies are precision tools used the cold heading process, which is a manufacturing technique for forming metal parts. Cold heading involves rapidly deforming a metal blank at room temperature to create a finished part shape.

Tungsten carbide is a popular material for cold carbide cold heading pellets due to its exceptional hardness, wear resistance, and strength. It is a composite material made by combining tungsten carbide particles with a cobalt binder. This combination results in a material that is extremely hard and able to withstand high compressive forces without deforming.

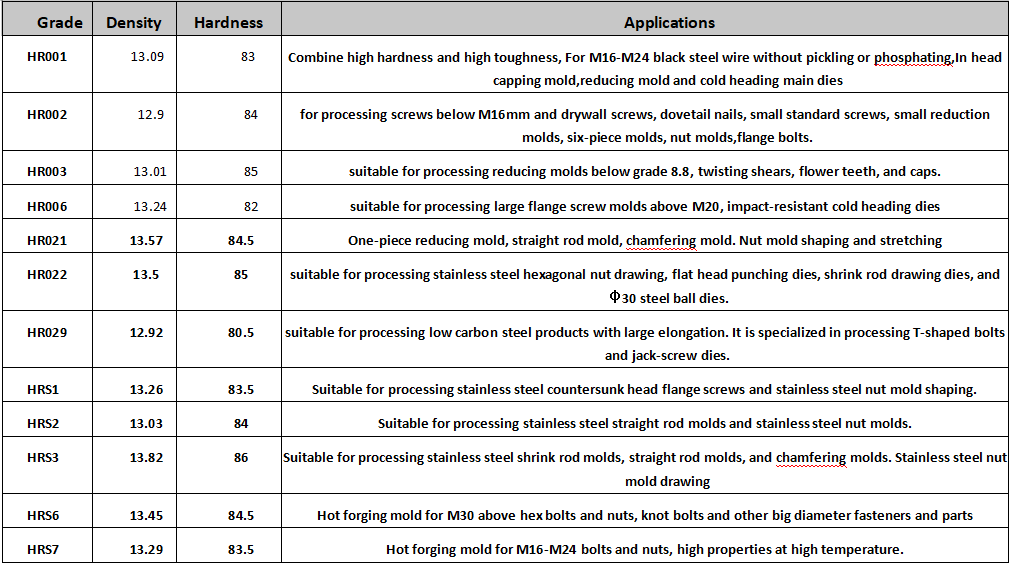

Item name :

Tungsten Carbide Cold Heading Die for Multi Station Cold Heading Machine Main DieGrade :

HR00 HRS ZHDHardness :

HRA82~85Cobalt % :

18~25%grain size :

0.6~2.6umUsage :

Cold heading Dies Hot Forging DieLogo :

HENGRUIpackage :

bubble plastic bag +plastic casesOther main products of HengRui Carbide.

Detailed Description:

Overall, tungsten carbide cold heading dies are critical tools in the cold heading industry, contributing to efficient and high-quality production of metal parts.

If the selected grade is prone to early cracking and damage during use, a grade with higher toughness should be selected; if the selected grade is prone to early wear and damage during use, a grade with higher hardness and good durability should be selected.

The following grades: YG15C, YG18C, YG20C, YG22C, YG25C from left to right, the hardness decreases, the wear resistance decreases, and the wear resistance increases; vice versa.

| GRADE | Composition | Carbide Grain Size |

Properties | ||||||||||

| Binder | WC+others | Density | Hardness | Hardness | TRS | ||||||||

| (±0.5%) | (±0.5%) | ISO Classification |

g/cm³ | HRA±0.3 | HRC | MPA | |||||||

| HV30 | |||||||||||||

| ZHD82 | 27 | 73 | 2.6 | 13.3 | 81.7 | 61 | 2713 | ||||||

| ZHD82A | 25 | 75 | 2.6 | 13.3 | 82.7 | 63 | 2723 | ||||||

| ZHD84 | 23 | 77 | 2.6 | 13.52 | 83.7 | 64.5 | 2800 | ||||||

| YG20C | 23 | 77 | 2.6 | 13.81 | 83.7 | 64.5 | 2800 | ||||||

| ZHD86 | 21 | 79 | 2.6 | 13.52 | 84.7 | 66 | 2976 | ||||||

| HR001 | 23.5 | 76.5 | 2.6 | 13.09 | 83 | 63.5 | 2700 | ||||||

| HR002 | 25 | 75 | 1.4 | 12.9 | 84 | 65.3 | 3305 | ||||||

| HR003 | 24 | 76 | 1.2 | 13.01 | 85 | 66.6 | 3550 | ||||||

| HR004 | 23 | 77 | 1.4 | 13.04 | 85 | 66.6 | 3500 | ||||||

| HR005 | 10 | 90 | 1.2 | 14.46 | 89.5 | 75.1 | 3700 | ||||||

| HR006 | 23 | 77 | 2.8 | 13.24 | 82 | 61.5 | 2700 | ||||||

| HR007 | 16 | 84 | 1.6 | 13.8 | 87 | 70.4 | 3700 | ||||||

| HR009 | 17 | 83 | 1.4 | 13.73 | 86 | 67.9 | 3500 | ||||||

| HR011 | 12.5 | 87.5 | 1.4 | 14.28 | 88 | 72.2 | 3600 | ||||||

| HR021 | 18.5 | 81.5 | 2.8 | 13.57 | 84.5 | 65.9 | 2900 | ||||||

| HR022 | 19 | 81 | 2.4 | 13.5 | 85 | 66.6 | 3400 | ||||||

| HR023 | 15 | 85 | 2.6 | 13.79 | 86 | 67.9 | 3100 | ||||||

| HR029 | 26 | 74 | 3.2 | 12.92 | 80.5 | 59 | 2900 | ||||||

| HR012 | 25 | 75 | 1.2 | 13.17 | 84 | 65.3 | 3000 | ||||||

| HRS1 | 19.5 | 80.5 | 2.4 | 13.26 | 83.5 | 64..5 | 2900 | ||||||

Q1: Are you a factory or a trading company?

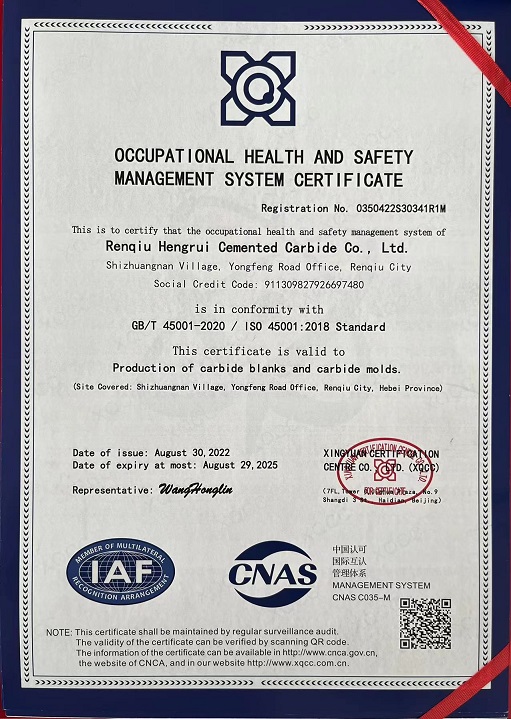

We are a factory with 25 years of production experience.

Q2: Where is your factory located?

We are located in Renqiu City, Hebei Province, adjacent to Beijing

Q3: How can we trust your company?

We support Alibaba Trade Insurance, 100% product quality guarantee, 100%

On-time shipping protection, 100% payment protection on your covered amount.

Q4: What is your delivery time?

For normal types for which we have molds, it will take 7-15 working days after payment is received.

Tags :