-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

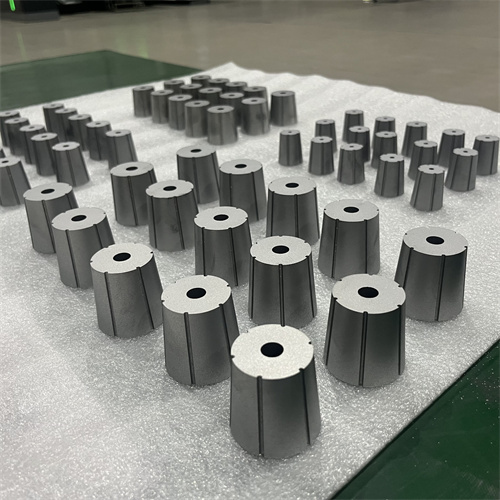

Tungsten Carbide Nuts Forming Die Steel Nuts Mold

A nuts forming die, also known as a nut forging die, is a specialized tool used in the production of nuts through a metalworking process called nut forming or nut forging. The nut forming process involves shaping a heated metal blank into the desired nut shape using a combination of forging and extrusion.

Item name :

GT55 Equivalent Tungsten Carbide Cold Heading Dies For FastenersGrade :

GT55Hardness :

HRA82.7Cobalt % :

25%grain size :

2.0 umUsage :

forging heading formingLogo :

HENGRUIpackage :

bubble plastic bag +plastic casesOther main products of HengRui Carbide.

Detailed Description:

Here is a simplified overview of the process:

Blank preparation: The raw material, typically a metal wire or rod, is cut into appropriate lengths to serve as blanks for forming the nuts. The blanks are usually slightly larger in diameter than the final nut size.

Heating: The blanks are heated to an elevated temperature to increase the material's ductility and reduce its resistance to deformation. Heating can be done using furnaces or induction heaters.

Transfer to the die: The heated blanks are transferred to the nuts forming die, which consists of two or more halves with cavities that match the desired nut shape. The blanks are positioned in the die cavities.

Forming operation: The die halves are brought together under high pressure, exerting forces on the blanks. The blanks are compressed and forced to flow into the intricate shape of the die cavity, resulting in the desired nut profile.

Flash formation: During the forming operation, excess material called flash is formed. Flash helps in filling the die cavities completely and prevents material leakage.

Flash trimming: After the forming operation, the excess flash material is trimmed off, either manually or using automated trimming processes.

Cooling and ejection: Once the forming and trimming are complete, the formed nuts are cooled, typically through a water quenching process. The cooled nuts are then ejected from the die.

Finishing operations: The formed nuts may undergo various finishing operations, such as sizing, threading, and surface treatment, to achieve the desired dimensions, thread quality, and appearance.

The nuts forming die is a critical component in this process, as it defines the shape and dimensions of the final nut. It is typically made from hardened tool steel to withstand the high pressures and temperatures involved in the nut forming process. Dies are precision-engineered to ensure consistent and accurate nut production.

Q1: Are you a factory or a trading company?

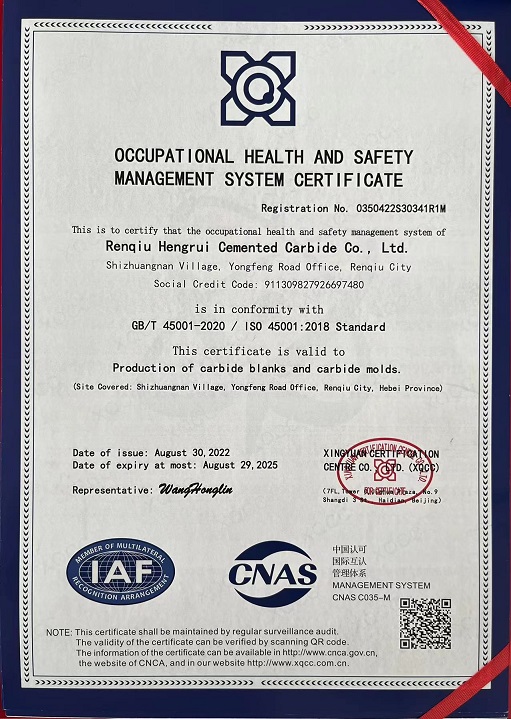

We are a factory with 25 years of production experience.

Q2: Where is your factory located?

We are located in Renqiu City, Hebei Province, adjacent to Beijing

Q3: How can we trust your company?

We support Alibaba Trade Insurance, 100% product quality guarantee, 100%

On-time shipping protection, 100% payment protection on your covered amount.

Q4: What is your delivery time?

For normal types for which we have molds, it will take 7-15 working days after payment is received.

Tags :