-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

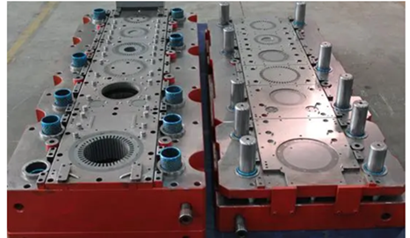

Progressive molds, also known as progressive dies or progressive tooling, are specialized molds used in manufacturing processes, particularly in metalworking and stamping operations. They are designed to perform a sequence of operations on a work piece as it moves through the mold, resulting in the creation of a finished part.

Progressive molds consist of multiple stations or stages, each designed to perform a specific operation on the work piece. These stations are arranged in a sequential order, allowing the work piece to move from one station to the next in a progressive manner. As the work piece advances through the mold, it undergoes a series of operations, such as cutting, bending, punching, forming, or extruding, to transform the initial material into the desired final shape.

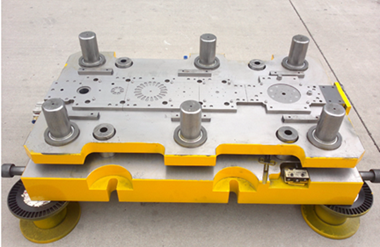

The main advantage of progressive molds is their ability to perform multiple operations in a single pass, increasing the efficiency and productivity of the manufacturing process. With each stroke of the press, a new work piece is fed into the mold, while the previously processed work pieces move forward to the next station. This continuous feed and movement allow for high-speed production and reduced cycle times.

Progressive molds are commonly used in the mass production of components or parts that require multiple operations. They are particularly suited for producing complex parts with precise dimensions and tolerances. Examples of products made using progressive molds include automotive components, electrical connectors, brackets, fasteners, and other stamped metal parts.

The design and construction of progressive molds require careful consideration of factors such as the material properties of the work piece, the sequence of operations, the alignment and positioning of the stations, and the mechanisms for feeding and transferring the work pieces. The molds are typically made of hardened tool steel to withstand the forces and wear associated with high-speed stamping operations