-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

When choosing tungsten steel mold plates, you should not only look at its grade, but also focus on understanding its physical properties, such as the proportion of tungsten carbide and cobalt in the raw materials, hardness, density, bending strength, elastic modulus and thermal expansion. coefficient

Item name :

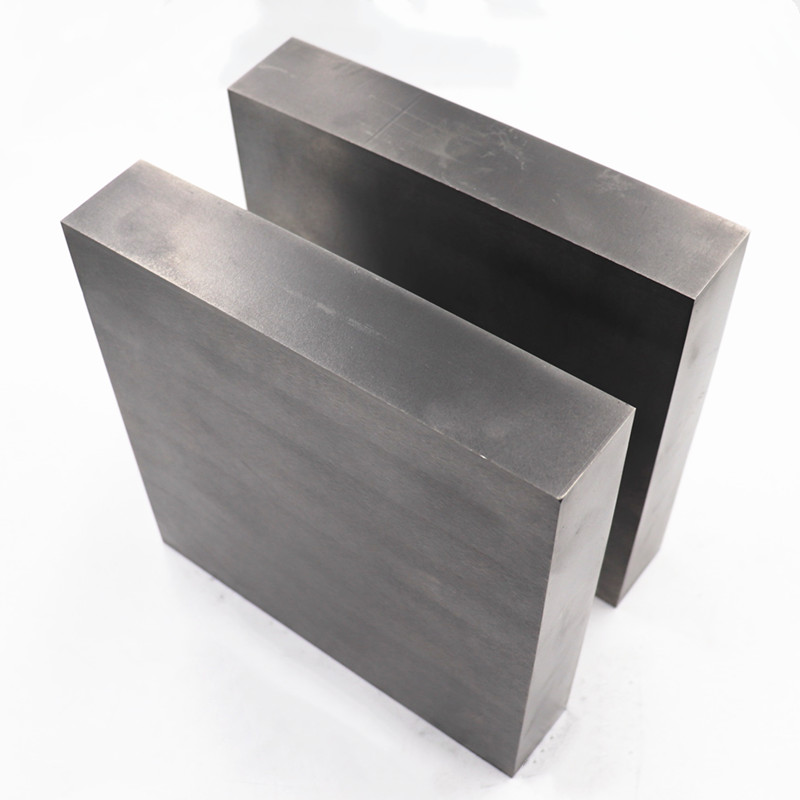

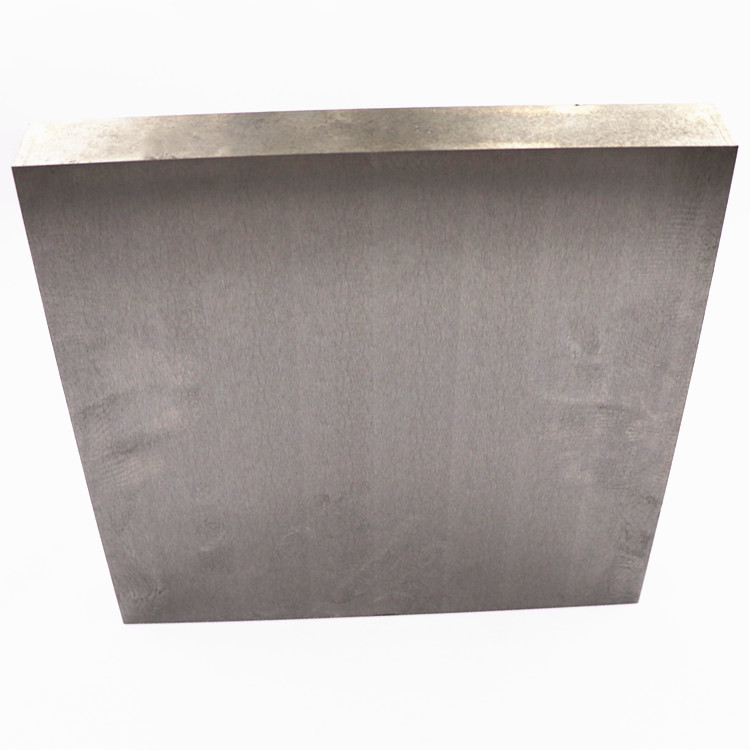

Tungsten carbide plateGrade :

YG8 YG11 YG15Hardness :

HRA83~89Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

TUNGSTEN CARBIDE PLATELogo :

HENGRUIpackage :

cartonDetailed Description:

The size of the tungsten carbide plate mold blank should be accurate. Accurate blank size can greatly reduce the workload of mold making, improve production efficiency, and reduce production costs.

To ensure that tungsten steel plate materials meet the working conditions requirements, attention should be paid to the following five points:

1. Wear resistance: The most basic and important wear resistance of mold materials. The main factor affecting wear resistance is hardness. The higher the hardness of the material used to make mold parts, the smaller the amount of wear and the better the wear resistance.

In addition, wear resistance is also closely related to the type, quantity, shape, size and distribution of carbides in the material, sintering process, and subsequent processing. The content (content) of cobalt in tungsten steel materials directly affects the hardness of the material. Generally speaking, the less cobalt content, the higher the hardness, and the higher the bending strength.

2. Strong toughness: Molds that often bear large impact loads are prone to brittle fracture due to their poor toughness. In order to prevent the mold from suddenly breaking during operation, the tungsten steel mold is required to have high strength and toughness.

The factors that determine the toughness of the mold mainly depend on the carbon content, grain size and organizational state of the material.

3. Heat and cold fatigue resistance: During the working process, the mold is either repeatedly heated or cooled, which can easily cause surface cracks and peeling due to tension and pressure changes on the cavity surface, increasing friction and hindering the mold. Plastic deformation reduces dimensional accuracy, resulting in mold failure. The main cause of failure of hot work molds is thermal fatigue. This type of mold should have high thermal fatigue resistance.

4. Fatigue fracture resistance: The mold is prone to fatigue fracture due to long-term cyclic stress during operation. The strength, toughness, hardness, and inclusion content of the mold material determine the fatigue fracture resistance of the mold.

5. High temperature resistance: The mold will generate very high temperatures during long-term continuous high-speed punching work. It is well known that high temperatures will reduce the hardness and strength, causing premature wear or plastic deformation of the mold and failure. Therefore, the mold material should have high anti-tempering stability to ensure that the mold has high hardness and strength at the working temperature.

Tags :