-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

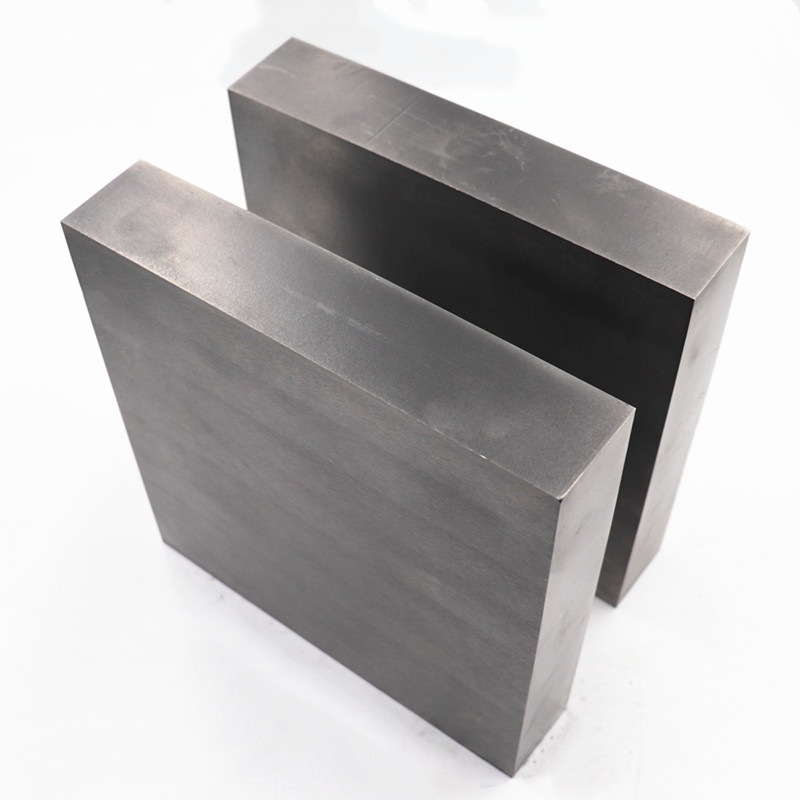

Tungsten Carbide Plate are Used to make Tungsten Carbide Punching Dies. It can be used to make high-speed punching dies and multi-station progressive dies for punching copper, aluminum, stainless steel, cold-rolled plates, EI sheets, Q195, SPCC, silicon steel sheets, hardware, standard parts, upper and lower punches and other thin sheets.

Item name :

Tungsten carbide cold heading blankGrade :

YG20Hardness :

HRA84~89Cobalt % :

15~25%grain size :

0.6~2.6umUsage :

TUNGSTEN CARBIDE PLATELogo :

HENGRUIpackage :

cartonDetailed Description:

Used to make wear-resistant knives. Such as knives used in the woodworking industry, plastic crushing knives, etc.

Used to make high-temperature resistant parts, wear-resistant parts, and anti-shielding parts. Such as machine tool guide rails, ATM anti-theft reinforcement plates, etc.

Used to make corrosion-resistant parts in the chemical industry.

Radiation protection and anti-corrosion materials for medical equipment. The material properties of cemented carbide plates for different uses are not consistent. When using them, carbide plates of the appropriate material should be selected according to the purpose.

YG20 stamping carbide tungsten plate tungsten carbide plate tungsten steel plate high hardness alloy mold plate product details:

1. The raw material is virgin tungsten carbide powder, which has low impurity content and stable physical properties of the board.

2. Using spray drying technology, the material is protected by high-purity nitrogen under fully sealed conditions, which effectively reduces the possibility of oxygenation during the preparation process of the mixture. The purity is better and the material is less likely to become dirty.

3. The density of the board is uniform: It is pressed with a 300Mpa isostatic press to effectively avoid the occurrence of pressing defects and the density of the board blank is more uniform.

4. The plate has excellent density and good strength and hardness indicators: using ship low-pressure sintering technology, the pores inside the plate can be effectively reduced and the quality is more stable.

5. Using cryogenic treatment technology, the internal metallographic structure of the plate can be improved, and the internal stress can be greatly reduced to avoid the occurrence of cracks during the cutting and forming process of the plate.

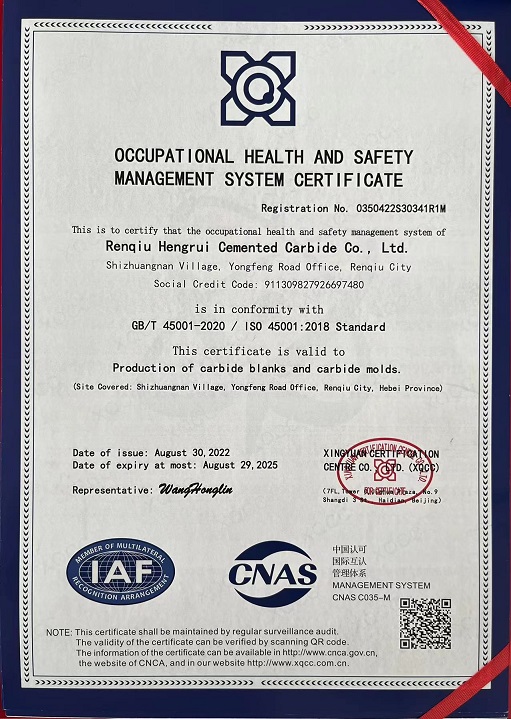

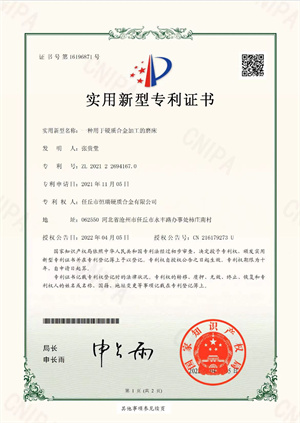

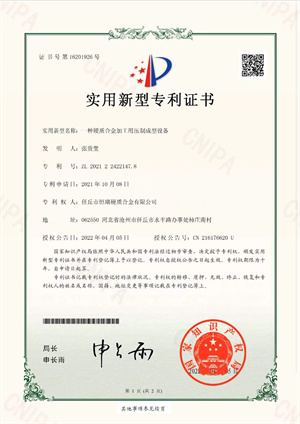

Renqiu Hengrui Cemented Carbide Co., Ltd. is mainly engaged in the manufacturing and mold processing of cemented carbide, tungsten carbide, cobalt powder, and alloy molds. The products include blanks, wire drawing, extubation and shrinking rods, straight rods, special shapes, standard parts molds, odd-shaped molds and other types. The force factory has equipment and has been tested and perfected. It has a long service life, is not disposable, and can be repaired and used many times. The service life remains unchanged after repair. Our factory has always focused on technology development and strict quality inspection. Mastering the manufacturing and development technology of alloy molds and having many excellent engineering and technical personnel, our factory has achieved great breakthroughs in the manufacturing of traditional molds and special-shaped molds, enabling it to meet various requirements.

Tags :