-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

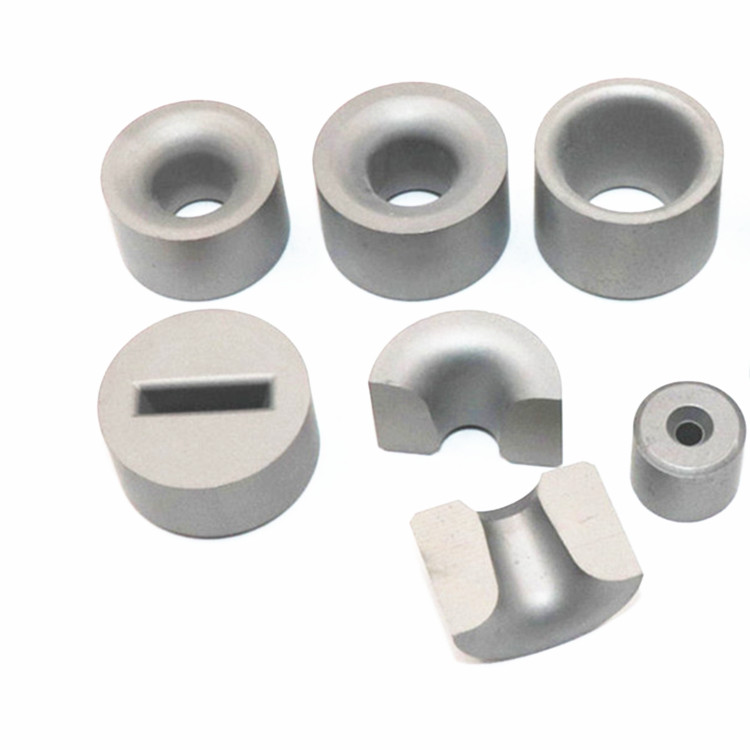

Tungsten Carbide Wire Drawing Die YG6 YG8 is composed of tungsten carbide (WC) and cobalt (Co). The content of tungsten carbide is about 94% and 92%, and the content of cobalt is about 6% and 8%. This material is known for its excellent hardness, wear resistance and good impact resistance toughness, and is often used in various mechanical equipment and tools, drawing molds, etc.

Item name :

Cemented Carbide wire drawing dieGrade :

YG6 YG8Hardness :

HRA89~90Cobalt % :

6~8%grain size :

0.6~2.6umUsage :

wire drawing dieLogo :

HENGRUIpackage :

cartonDetailed Description:

After decades of development, many new Tungsten Carbide Wire Drawing Die materials have emerged. According to the type of material, wire drawing dies can be divided into alloy steel dies, carbide dies, natural diamond dies, polycrystalline diamond dies, CVD diamond dies and ceramic dies. The development of new materials has greatly enriched the application range of wire drawing dies and increased the service life of wire drawing dies.

Carbide molds are made of carbide. Cemented carbide is a tungsten-cobalt alloy whose main components are tungsten carbide and cobalt. Tungsten carbide is the "skeleton" of the alloy, which mainly plays a hard and wear-resistant role; cobalt is the bonding metal and is the source of the alloy's toughness. Therefore, compared with alloy steel molds, cemented carbide molds have the following characteristics: high wear resistance, good polishability, low adhesion, small friction coefficient, low energy consumption, and high corrosion resistance. These characteristics make carbide wire drawing The mold has a wide range of processing adaptability and has become the most commonly used wire drawing die today.

| GRADE | Composition | Carbide Grain Size |

Properties | ||||||||||

| Binder | WC+others | Density | Hardness | Hardness | TRS | ||||||||

| (±0.5%) | (±0.5%) | ISO Classification |

g/cm³ | HRA±0.3 | HRC | MPA | |||||||

| HV30 | |||||||||||||

| ZHD82 | 27 | 73 | 2.6 | 13.3 | 81.7 | 61 | 2713 | ||||||

| ZHD82A | 25 | 75 | 2.6 | 13.3 | 82.7 | 63 | 2723 | ||||||

| ZHD84 | 23 | 77 | 2.6 | 13.52 | 83.7 | 64.5 | 2800 | ||||||

| YG20C | 23 | 77 | 2.6 | 13.81 | 83.7 | 64.5 | 2800 | ||||||

| ZHD86 | 21 | 79 | 2.6 | 13.52 | 84.7 | 66 | 2976 | ||||||

| HR001 | 23.5 | 76.5 | 2.6 | 13.09 | 83 | 63.5 | 2700 | ||||||

| HR002 | 25 | 75 | 1.4 | 12.9 | 84 | 65.3 | 3305 | ||||||

| HR003 | 24 | 76 | 1.2 | 13.01 | 85 | 66.6 | 3550 | ||||||

| HR004 | 23 | 77 | 1.4 | 13.04 | 85 | 66.6 | 3500 | ||||||

| HR005 | 10 | 90 | 1.2 | 14.46 | 89.5 | 75.1 | 3700 | ||||||

| HR006 | 23 | 77 | 2.8 | 13.24 | 82 | 61.5 | 2700 | ||||||

| HR007 | 16 | 84 | 1.6 | 13.8 | 87 | 70.4 | 3700 | ||||||

| HR009 | 17 | 83 | 1.4 | 13.73 | 86 | 67.9 | 3500 | ||||||

| HR011 | 12.5 | 87.5 | 1.4 | 14.28 | 88 | 72.2 | 3600 | ||||||

| HR021 | 18.5 | 81.5 | 2.8 | 13.57 | 84.5 | 65.9 | 2900 | ||||||

| HR022 | 19 | 81 | 2.4 | 13.5 | 85 | 66.6 | 3400 | ||||||

| HR023 | 15 | 85 | 2.6 | 13.79 | 86 | 67.9 | 3100 | ||||||

| HR029 | 26 | 74 | 3.2 | 12.92 | 80.5 | 59 | 2900 | ||||||

| HR012 | 25 | 75 | 1.2 | 13.17 | 84 | 65.3 | 3000 | ||||||

| HRS1 | 19.5 | 80.5 | 2.4 | 13.26 | 83.5 | 64..5 | 2900 | ||||||

Tags :